Building a custom gravel bike for adventure touring involves selecting the right materials, like a durable steel or lightweight carbon frame, and choosing versatile wheel sizes such as 700c or 650b with wider tires for comfort and traction. You’ll want to customize the gearing for varied terrains and optimize your fit with slack head angles and cockpit adjustments. Considering cost, maintenance, and support, a well-built bike can last for years. Keep exploring to uncover each step in creating your perfect adventure machine.

Key Takeaways

- Selecting lightweight, durable frame materials like carbon fiber or titanium optimizes weight and longevity for long-distance touring.

- Choosing 700c wheels with medium-width tires offers efficient rolling on paved and gravel surfaces, enhancing versatility.

- Customizing gear ratios with larger cassettes and single or double chainrings provides a broad gear range for varied terrains.

- Optimizing fit with slack head angles, lower bottom brackets, and flared handlebars ensures stability and comfort during extended rides.

- Incorporating vibration damping components and tubeless tires reduces fatigue and minimizes maintenance for reliable touring performance.

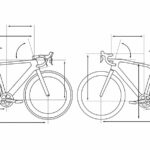

Selecting the Ideal Frame Material and Design

Choosing the right frame material is essential when building a custom gravel bike because it directly impacts the bike’s weight, durability, and riding comfort. If you want a lightweight bike with excellent power transfer, carbon fiber is a top choice, though it can be prone to impact damage. Aluminum alloy offers durability, affordability, and a lightweight profile, making it practical for many riders. Steel provides unmatched durability and vibration absorption, delivering a smooth ride, especially on rough terrains. Titanium blends strength, durability, and a comfortable feel, and it’s highly resistant to corrosion, suitable for harsh environments. Hybrid frames combine materials to balance weight, performance, and comfort. Your choice depends on your riding style, terrain, and budget, but selecting a suitable material sets the foundation for a successful gravel bike build. Additionally, understanding the signs of spoilage in consumables like lemon juice can help maintain your health and safety during your adventures, especially with the help of AI-powered data analytics to monitor freshness. An awareness of personal development tools like mindfulness techniques and goal setting can also enhance your overall riding experience and safety on long journeys. Moreover, considering spiritual and emotional considerations can support mental resilience during challenging rides or setbacks. Staying informed about the latest advancements in bicycle technology can also help you make more educated decisions about your build and maintenance.

Choosing Wheel Sizes and Tire Configurations for Versatility

Selecting the right wheel size and tire setup is essential for maximizing your gravel bike’s versatility across different terrains. If you plan to ride mostly on smoother surfaces, 700c wheels with medium-width tires deliver efficient rolling and speed.

For more technical, off-road sections, 650b wheels with wider, knobblier tires offer superior traction and control. Many gravel frames can accommodate both sizes, giving you flexibility, but check compatibility and tire clearance first.

When choosing tires, consider internal rim width, tire volume, and terrain. Wider tires with lower pressures provide comfort and grip on rough surfaces, while narrower tires are better for on-road efficiency. Tire volume influences ride comfort and traction, especially on uneven terrain.

Using tire technology, such as advanced rubber compounds and tread patterns, can further enhance performance tailored to your riding style. Tubeless setups improve performance and reduce flats, making your bike more reliable on long adventures. Additionally, understanding wheel size compatibility ensures you select the best options for your frame and riding style, helping your bike adapt seamlessly to all conditions.

Customizing Gearing Systems for Diverse Terrains

Optimizing your gravel bike’s gearing system allows you to tackle a wide range of terrains with confidence. You can choose between double chainring setups, like 46/36 or 48/31, for versatility or go with a single ring, such as 40 or 42 teeth, for simplicity and reliability. Mullet drivetrains combine road or gravel shifters with MTB cassettes, expanding gear range for steep climbs and technical descents. Gravel-specific groupsets like Shimano GRX, SRAM XPLR, or Campagnolo Ekar offer wider gear options. Customizing your gear ratios—selecting larger cassettes (e.g., 10-50t) or smaller chainrings—helps adapt to diverse terrains. Additionally, understanding your bike’s gear efficiency can help you choose the most effective setup for your riding style. Recognizing the family backgrounds of certain cycling personalities can also provide insight into their dedication and approach to the sport. Whether you prefer electronic or mechanical shifting, tailoring your gearing ensures smooth, efficient performance on everything from steep ascents to fast descents.

Personalizing Fit and Comfort for Extended Tours

Ensuring a comfortable and personalized fit is essential when tackling extended gravel tours, as it directly impacts your endurance and enjoyment. Start by fine-tuning your frame geometry—slacker head angles (70-71°) improve stability, while a lower bottom bracket (265-280mm) boosts cornering and reduces pedal strikes.

Prioritize a personalized fit with optimized geometry for stability and control on long gravel rides.

Adjust your cockpit with flared handlebars (16-24° flare) and shallow drop bars to reduce wrist and back strain, respectively. Use gel-padded tape for vibration damping.

Fine-tune saddle height (5-10mm lower than road bikes) and rearward saddle position to balance comfort and technical maneuverability, while pressure-relief cutouts prevent numbness.

Incorporate vibration damping solutions like high-volume tires, carbon seatposts, and suspension stems to absorb trail shocks, ensuring comfort over long hours.

Evaluating Cost and Value of a Fully Custom Build

Evaluating the cost and value of a fully custom gravel bike requires balancing your budget against the specific benefits you’ll gain. Custom builds start at $5,000, with top-tier options exceeding $12,000, incorporating materials like titanium or steel, bespoke geometry, and advanced components.

While these bikes offer superior durability, weight savings, and tailored handling, the cost increases markedly compared to mid-range prebuilt bikes costing between £1,000 and £2,000.

Custom frames and components, such as titanium forks and tailored finishes, add to the expense but can provide decades of reliable use.

Keep in mind, diminishing returns set in around $3,000 for upgrades, and resale value is limited.

Ultimately, consider whether the enhanced ride quality, durability, and personalization justify the higher investment for your adventure touring needs.

Ensuring Support and Maintenance for Long-Term Adventure

Maintaining your custom gravel bike for long-term reliability starts with understanding routine upkeep and being prepared for trailside repairs. Regularly clean and lubricate your chain every 100-200 miles to prevent wear, and wash your bike after muddy rides to protect components.

Inspect tires for cuts, embedded debris, and tread wear, and check spoke tension to keep wheels true. Monitor brake pads and replace them before they thin to 1mm. Carry a toolkit with essentials like a chain breaker, tire levers, patches, and a multi-tool.

Practice quick repairs such as chain links and tire booting. Regrease bearings annually and upgrade cables for precise shifting. These steps help you stay confident on long adventures and ensure your bike remains dependable mile after mile.

Frequently Asked Questions

How Long Does It Take to Build a Custom Gravel Bike?

You wonder how long it takes to build a custom gravel bike. The timeline depends on complexity, from 5 to 16 weeks. Pre-designed frames take about 3 weeks, while full custom builds with paint can take up to 9 weeks.

Factors like component availability, assembly skill, and paint curing add to the time. You should plan for delays and guarantee your workspace is ready to keep the process smooth.

Can I Upgrade Components After the Initial Build?

Yes, you can definitely upgrade components after the initial build. You’re free to swap out wheels, tires, handlebars, or add new mounts to improve performance, comfort, or functionality.

Just guarantee compatible parts fit your bike’s frame and drivetrain. Upgrading is a great way to tailor your bike for different terrains or riding styles, and it keeps your ride fresh and exciting without needing a whole new bike.

What Are the Best Options for Eco-Friendly Frame Materials?

Imagine building a bike that’s kind to the planet; that’s what choosing eco-friendly frame materials offers. You should consider bamboo for its strength and sustainability, recycled aluminum to reduce waste, or BioMid Fiber for lightweight durability.

Recycled carbon fiber also stands out, combining performance with environmental responsibility. These options help lower your carbon footprint, promote recycling, and guarantee your bike remains robust and adaptable for all your adventures.

How Do I Determine the Right Tire Pressure for Different Terrains?

To find the right tire pressure for different terrains, start with your tire and rider weight as a baseline, then adjust accordingly.

For loose gravel or mud, lower the pressure by 5-10 PSI for better grip.

On rocky or technical terrain, set it between 25-35 PSI for comfort.

For hardpack or pavement, increase to 35-50 PSI to reduce rolling resistance.

Use a gauge and test ride to fine-tune pressures for ideal traction and comfort.

Are There Financing Options for Custom Bike Purchases?

You can find several financing options for custom bike purchases. Providers like Affirm offer flexible plans with zero percent APR.

While Synchrony Financial and Citizens Pay provide credit-based options often linked to brands like Trek and Specialized. Many bike shops also offer in-store financing or layaway plans.

These options let you spread payments over months, sometimes with no down payment, making it easier to afford your dream bike.

Conclusion

Building your custom gravel bike is like crafting a trusty steed for endless adventures. By choosing the right materials, wheel sizes, and gear systems, you create a machine that’s tailored to your needs. Prioritizing comfort and maintenance makes certain it’ll serve you well for miles to come. Think of your bike as a reliable partner, ready to take you on any terrain—each detail adding up to a perfect adventure companion.