Have you ever been curious about how bicycles, those amazing two-wheeled machines, are manufactured? Get ready to be amazed as I guide you through the fascinating and detailed process.

From the design and engineering phase to the final assembly, every step is a testament to human ingenuity and precision.

Join me as we delve into the fascinating world of material selection, frame manufacturing, component production, and more.

Get ready to pedal through the gears of knowledge and discover the artistry behind the creation of a bicycle.

Key Takeaways

- Functionality testing, safety testing, and final assembly are crucial steps in the manufacturing and quality control process of bicycles.

- Painting and finishing, as well as packaging efficiency, are important aspects of the finishing and packaging stage.

- Shipping logistics and timely delivery play a significant role in the shipping and logistics of bicycles.

- Providing excellent customer service, support, and ensuring customer satisfaction are essential for building positive relationships with customers.

Design and Engineering

Designing and engineering a bicycle involves considering factors such as aerodynamics and material selection. Design challenges arise when creating a bicycle that is both visually appealing and functional. Ergonomic considerations play a crucial role in determining the overall comfort and safety of the rider.

The frame geometry and handlebar positioning must be carefully designed to ensure an optimal riding position and reduce the risk of strain or injury. Additionally, the design must address the challenge of balancing stability and maneuverability, allowing the rider to navigate various terrains with ease.

As we move into the next section about material selection, it is important to note that the design and engineering process go hand in hand, with material choices directly impacting the overall performance and durability of the bicycle.

Material Selection

When selecting materials, it’s important to consider factors such as durability and weight. These factors play a crucial role in the overall performance and quality of the bicycle. Sourcing materials is a critical step in the manufacturing process, as it determines the strength and longevity of the final product. Sustainability in manufacturing is also a key consideration, with a growing emphasis on using eco-friendly materials and processes.

In order to achieve these goals, the material selection process involves evaluating different options and their properties. Here are three important factors to consider:

- Strength: The material must be able to withstand the stresses and strains of everyday use.

- Weight: A lighter material can contribute to improved efficiency and maneuverability.

- Cost: Finding a balance between quality and affordability is essential.

Considering these factors, the next step in the bicycle manufacturing process is frame manufacturing. This involves shaping and assembling the materials to create the foundation of the bicycle.

Frame Manufacturing

To manufacture the frame, I need to shape and assemble the materials to create the foundation of the bike. The most common material used for bike frames is steel, due to its durability and strength. However, other materials such as aluminum, titanium, and carbon fiber are also popular choices. Welding techniques are commonly used to join the frame tubes together, ensuring a strong and secure connection.

Carbon fiber technology has also made significant advancements in frame manufacturing. Carbon fiber frames offer superior strength-to-weight ratio and can be molded into complex shapes. This allows for increased customization and performance.

Moving on to the next section about component production, the frame serves as the backbone of the bicycle, providing support and stability for other parts to be attached.

Component Production

When it comes to component production in bicycle manufacturing, two key aspects to consider are the manufacturing of wheels and hubs, as well as the production of handlebars and brakes.

The process of manufacturing wheels and hubs involves precision engineering to ensure optimal performance and durability.

Similarly, producing handlebars and brakes requires attention to detail to create ergonomic designs that provide comfort and efficient control for riders.

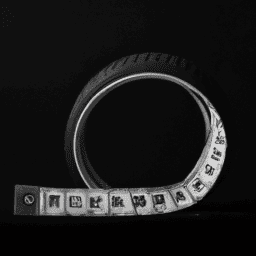

Manufacturing Wheels and Hubs

The first step in manufacturing bicycle wheels and hubs is selecting the appropriate materials. To ensure durability and strength, I choose high-quality aluminum alloy for the hubs and rims.

Next, I gather stainless steel wire to manufacture spokes that will provide stability and support to the wheel. The manufacturing process involves cutting, threading, and bending the wire to create the desired shape and length for each spoke.

Once the spokes are ready, I carefully assemble them onto the hub and attach the rim using advanced welding techniques.

Finally, I perform wheel truing, a process that ensures the wheel spins smoothly and remains true to its alignment. This meticulous process guarantees a high-quality wheel that will provide a smooth and reliable ride.

Moving on to producing handlebars and brakes, I focus on precision and functionality.

Producing Handlebars and Brakes

Producing handlebars and brakes requires careful attention to precision and functionality.

When it comes to handlebars, manufacturers understand the importance of customized designs that cater to different riding styles and preferences. From classic drop bars to modern flat bars, there is a wide range of options available. These handlebars are crafted with lightweight materials like aluminum or carbon fiber to ensure durability and reduce weight.

Additionally, innovative brake technology plays a crucial role in ensuring the safety of riders. Advanced braking systems like disc brakes provide better stopping power and modulation, enhancing control and confidence on the road.

As we move into the assembly process, the handlebars and brakes are integrated seamlessly to create a complete bicycle that is ready to hit the road.

Assembly Process

To make a bicycle, workers assemble different parts together using various assembly techniques to ensure production efficiency.

The assembly process begins by attaching the frame to the wheels using specialized tools, such as wrenches and screwdrivers.

The handlebars are then mounted onto the frame, ensuring they are aligned properly for optimal control and comfort.

Next, the brakes are installed, with careful attention paid to their positioning and functionality. This step involves connecting the brake levers to the handlebars and attaching the brake calipers to the frame.

Once all the components are assembled, a thorough quality control check is performed to ensure that the bicycle meets the highest standards of safety and performance. This ensures that every bicycle that leaves the production line is of the utmost quality and ready for use.

Moving on to the next section, quality control ensures that all parts are functioning correctly.

Quality Control

When it comes to quality control in the bicycle assembly process, two key points must be considered: inspecting the frame for defects and imperfections, and testing components for functionality and safety.

To ensure a high-quality product, I meticulously inspect each frame for any signs of damage, such as cracks or dents, that could compromise its integrity.

Additionally, I rigorously test each component, such as brakes and gears, to ensure they function properly and meet safety standards.

By focusing on these critical aspects of quality control, I can confidently deliver a reliable and safe bicycle to customers.

Inspecting Frame for Defects and Imperfections

Inspecting the frame for defects and imperfections is an important step in the bicycle manufacturing process. During this stage, we meticulously check the frame to ensure it meets our high-quality standards. Our defect detection process includes a thorough visual inspection and the use of advanced technology to identify any potential issues. To provide you with a better understanding, here is a breakdown of some of the common defects we look for:

| Defects | Imperfections |

|---|---|

| Cracks | Welding flaws |

| Dents | Paint blemishes |

| Misalignments | Surface scratches |

By carefully examining each frame, we can catch any defects early on and rectify them before they impact the overall quality of the bicycle. This rigorous quality assurance process ensures that our bicycles are reliable and durable. Moving forward, we will now shift our focus to testing components for functionality and safety, ensuring that every part of the bicycle performs flawlessly.

Testing Components for Functionality and Safety

Testing components for functionality and safety is an essential step in ensuring the reliability and durability of our bikes.

Functionality testing involves examining each component, such as the brakes, gears, and pedals, to ensure they are working properly and smoothly. This includes checking for any defects or malfunctions that could affect the overall performance of the bike.

Safety testing involves verifying that all components meet the necessary safety standards and regulations. This includes assessing the strength and stability of the frame, the effectiveness of the brakes, and the visibility of reflectors and lights.

By conducting these tests, we can guarantee that our bikes are not only functional but also safe for riders.

Moving on to the next section, painting and finishing adds the final touch to our meticulously crafted bicycles.

Painting and Finishing

To finish your bicycle, you’ll need to paint it and add the final touches. Painting is not only about aesthetics but also about protecting the frame from corrosion. Before painting, ensure the frame is clean and free from any grease or dirt. Choose a high-quality bicycle paint that is specifically designed for durability and weather resistance. You can choose from a variety of colors to personalize your bike. After applying the paint, allow it to dry completely before adding any additional finishes or decals. The drying time will depend on the type of paint used and environmental conditions. While waiting for the paint to dry, you can start gathering the components for the final assembly. This will ensure a smooth and efficient completion of your bicycle.

Final Assembly

After the meticulous painting and finishing process, the bicycle parts are ready to be brought together in the final assembly phase. This is where all the individual components are carefully fitted and secured to create the complete bicycle.

As the assembler, I start by attaching the wheels to the frame, making sure they are aligned and tightened properly. Then, I install the handlebars, brakes, and gears, ensuring that each part is correctly positioned and adjusted for optimal performance.

Once the final assembly is complete, a thorough inspection is conducted to guarantee the bicycle meets our high-quality standards. This includes checking for any defects, loose fittings, or misalignments.

Finally, the bicycle undergoes the packaging process, where it is carefully wrapped and protected to ensure it arrives in perfect condition to its destination.

Now, let’s move on to the next step of packaging and shipping, where the finished bicycles are prepared for their journey to customers.

Packaging and Shipping

To prepare the finished bicycles for their journey to you, we carefully package and ship them to ensure they arrive in perfect condition. Packaging efficiency and shipping logistics play a crucial role in this process.

We have developed an optimized packaging system that maximizes space utilization and minimizes the risk of damage during transportation. Each bicycle is meticulously wrapped in protective layers to safeguard the frame, components, and delicate parts. Additionally, we use high-quality packaging materials that provide excellent shock absorption and vibration resistance.

Our shipping logistics are carefully planned to ensure timely delivery. We work closely with reliable shipping carriers to optimize routes and minimize transit times. Tracking information is provided to keep you updated on the progress of your shipment.

As we transition into the subsequent section about customer service and support, you can rest assured that our commitment to your satisfaction extends beyond the packaging and shipping process.

Customer Service and Support

After the packaging and shipping process, customer service and support play a crucial role in ensuring customer satisfaction with their newly purchased bicycle.

As a manufacturer, it is important to provide comprehensive troubleshooting support to address any issues or concerns that customers may have. Our customer service team is trained to assist customers in a friendly and efficient manner, guiding them through the process of assembling and maintaining their bicycle.

We understand that timely and accurate support is essential to enhance the overall ownership experience. Whether it’s addressing technical difficulties, answering product-related questions, or providing guidance on maintenance and repairs, our dedicated team is committed to resolving customer issues promptly.

By offering reliable customer service and troubleshooting support, we aim to foster a positive relationship with our customers and ensure their continued satisfaction with our bicycles.

Frequently Asked Questions

What safety regulations are bicycles subject to during the manufacturing process?

During the manufacturing process of bicycles, safety regulations play a crucial role. These regulations ensure that bicycles meet specific standards for components, materials, and construction methods, ensuring the safety of riders.

How does the choice of materials affect the overall weight and durability of a bicycle?

The choice of materials in bicycle construction greatly impacts the overall weight and durability. By selecting lightweight materials such as carbon fiber or aluminum, the weight can be reduced while maintaining strength and durability for a longer-lasting bike.

Are there any specialized tools or machinery used in the frame manufacturing process?

In the frame manufacturing process, specialized tools and machinery are used to ensure precise alignment and balance. Welding techniques and material selection are crucial for production efficiency and quality control. The assembly process requires meticulous attention to detail.

How are the various bicycle components tested for quality and performance?

To ensure quality and performance, bicycle components undergo rigorous testing procedures. Performance standards are used to evaluate factors such as durability, strength, weight, and functionality. This ensures that only the highest-quality components are used in the manufacturing process.

What steps are taken to ensure the proper alignment and balance of the bicycle during the final assembly process?

To ensure proper alignment and balance during final assembly, alignment techniques like using alignment jigs and measuring tools are employed. Balancing methods, such as adjusting spoke tension and aligning the wheels, are also utilized to achieve optimal performance and stability.

Conclusion

In conclusion, creating a bicycle is a meticulous process that involves careful design, engineering, and material selection. From the manufacturing of the frame and components to the precise assembly and painting, every step is executed with utmost precision.

The final result is a masterpiece on wheels, crafted to perfection. Just like a well-oiled machine, a bicycle is a symphony of parts working together seamlessly, gliding through the world with grace and efficiency.

So, hop on and ride into the sunset, experiencing the freedom and exhilaration only a bicycle can provide.