Constructing a quadruple-wheeled bike is a thrilling and satisfying endeavor for those who have a passion for biking and do-it-yourself projects. Speaking from personal experience, having assembled my own four-wheeled bicycle, I can attest that while the task may present some obstacles, it is exceedingly gratifying. You not only end up with a distinctive and customized form of transport but also the pride of having constructed it on your own.

Before getting started, it’s important to gather all the necessary tools and materials. This includes everything from a welding machine and metal tubing to wheels, pedals, and a drivetrain system.

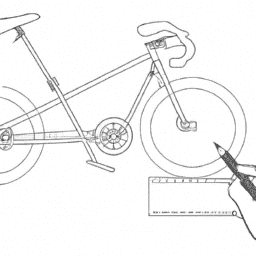

Once you have everything you need, it’s time to start designing and planning your four-wheel bicycle. This involves sketching out your ideas and taking measurements to ensure that your bicycle will be sturdy, safe, and comfortable to ride.

With a solid plan in place, you can start assembling the frame and installing the drivetrain, making adjustments as needed along the way.

By the end of the process, you’ll have a one-of-a-kind four-wheel bicycle that you can be proud of.

Key Takeaways

- Building a four-wheel bicycle is a challenging but rewarding DIY project that requires proper planning and consideration of riding needs, frame design, wheel size, and type.

- Customizable features can affect the ride’s comfort and efficiency, but budget considerations are important for selecting the right components.

- Proper alignment and regular maintenance are crucial for keeping the bicycle in good condition and ensuring a smooth and stable ride.

- Safety should always be a top priority throughout the building and riding process, and following manufacturer’s instructions is important for installation and maintenance.

Gather the Necessary Tools and Materials

You’ll need to grab a few essential tools and materials before you can get started building your four-wheel bicycle.

The materials needed to build a four-wheel bicycle include steel tubing, wheels, axles, bearings, and various hardware such as nuts and bolts.

You’ll also need tools like a hacksaw, a drill, a wrench, a tube bender, and a file to cut and shape the steel tubing into the desired shapes and sizes.

To start building your four-wheel bicycle, you’ll need to gather all the materials and tools required. It’s important to make sure you have everything you need before you begin, as it can be frustrating to have to stop mid-project to purchase additional supplies.

Once you have everything you need, it’s time to move on to the next step: designing and planning your four-wheel bicycle.

Design and Plan Your Four-Wheel Bicycle

When designing and planning my four-wheel bicycle, I need to consider my riding needs, choose a frame design, and select the appropriate wheel size and type.

To determine my riding needs, I’ll consider factors such as terrain, distance, and speed. Choosing the right frame design is important for stability and safety. I’ll need to decide between a delta or tadpole design.

Finally, selecting the appropriate wheel size and type will depend on factors such as weight capacity, terrain, and desired speed.

Consider Your Riding Needs

Assembling a four-wheel bicycle requires taking into account your riding needs, so it’s important to think about what kind of terrain you’ll be riding on. Customizable features such as suspension, gearing, and tire size can all play a role in making your ride more comfortable and efficient.

Additionally, budget considerations should be taken into account when deciding on these features. While it may be tempting to splurge on the latest and greatest components, it’s important to ensure that these choices align with your financial goals.

Once you’ve considered your riding needs and budget, the next step is to choose your frame design. This will ultimately determine the overall look and feel of your four-wheel bicycle, as well as its durability and stability. By carefully selecting a frame that meets your specific needs, you can ensure that your four-wheel bicycle will be a reliable and enjoyable mode of transportation.

Choose Your Frame Design

Selecting the perfect frame design for your ride can be a thrilling experience, as it determines the overall look and feel of your bike. The frame materials you choose will also affect the weight, durability, and cost of your bicycle.

There are several materials to choose from, including steel, aluminum, titanium, and carbon fiber. Steel is a classic choice for its durability and affordability, while aluminum is lightweight and corrosion-resistant. Titanium is strong and lightweight, but also the most expensive option. Carbon fiber is a popular choice for its strength and weight, but it comes with a higher price tag.

Once you have decided on the frame material, consider the customization options available for your chosen design. Some frames may have the option for adjustable seat heights or different lengths of the top tube to accommodate your riding style. You may also want to consider the color and finish of your frame to match your personal style.

Keep in mind that the customization options may affect the overall cost of your bicycle. With your frame design and customization options in mind, you can now move on to selecting the perfect wheel size and type for your four-wheel bicycle.

Select Your Wheel Size and Type

Now it’s time for you to pick the perfect size and style of wheels for your four-wheel bicycle. Wheel size considerations are crucial as they determine the overall performance of your ride.

The most common wheel sizes for four-wheel bikes are 20 inches and 26 inches. The smaller 20-inch wheels provide better maneuverability, while the larger 26-inch wheels offer better stability and speed. It’s important to consider the terrain you’ll be riding on and your personal preference when selecting your wheel size.

Types of wheels for four-wheel bicycles include pneumatic and solid rubber tires. Pneumatic tires are filled with air, providing a smoother and more comfortable ride. They also offer better traction and shock absorption, making them ideal for off-road terrain.

Solid rubber tires, on the other hand, are maintenance-free and puncture-resistant. They’re perfect for smooth surfaces and provide a more stable ride.

Now that you’ve chosen your ideal wheel size and type, it’s time to move on to assembling the frame of your four-wheel bicycle.

Assemble the Frame

So, now that I’ve designed and planned my four-wheel bicycle, it’s time to assemble the frame.

The first step is to either weld or join the frame, depending on the materials used.

Once that’s done, I’ll need to attach the wheels and axles to the frame, ensuring that they’re properly aligned and secured.

Finally, I’ll install the handlebars and brakes, making sure that they’re in the correct position for comfortable and safe riding.

Welding or Joining Your Frame

Before starting, make sure you’ve got all the necessary tools and materials for welding or joining your frame. You’ll need a welding machine, welding gloves, a welding helmet, a metal saw, a metal grinder, and metal clamps. Also, you’ll need to choose the materials for your frame, which can include steel, aluminum, or titanium. Consider the weight, strength, and cost of each material before making your choice.

Here are four things to keep in mind when welding or joining your frame:

-

Safety first. Always wear the appropriate protective gear, and make sure your workspace is well-ventilated.

-

Choose the right welding technique for your materials. MIG and TIG welding are popular options for steel and aluminum frames, while titanium frames require a specialized technique called ‘gas tungsten arc welding.’

-

Clean and prep your materials thoroughly before welding. Remove any rust, paint, or debris that could interfere with the welding process.

-

Take your time and practice. Welding is a skill that takes time and practice to master. Don’t rush the process, and be prepared to make mistakes along the way.

Now that your frame is welded or joined together, it’s time to move on to attaching the wheels and axles.

Attaching Wheels and Axles

To complete the assembly of your vehicle, it’s time to attach the wheels and axles, ensuring a smooth and stable ride. Proper alignment of the wheels and axles is crucial for this purpose.

Make sure the wheels are mounted on the axle straight and secure, and that the axle is attached to the frame at the correct angle. Different types of wheel and axle systems are available, so choose the type that suits your needs and budget.

After attaching the wheels and axles, it’s important to keep them in good condition with regular maintenance. Keep the wheels properly inflated and check the axles for any signs of wear and tear.

Lubricate the axles and bearings as needed to ensure a smooth ride. With the wheels and axles attached, it’s time to move on to the next step: installing handlebars and brakes.

Installing Handlebars and Brakes

Now it’s time for me to get a grip and install the handlebars and brakes. Choosing the right handlebar is crucial for the comfort and control of the rider. There are various types of handlebars available in the market, such as drop, flat, riser, and BMX.

I personally prefer a flat handlebar as it provides a more upright position, which is suitable for long rides. However, if you’re into more aggressive riding, then a drop handlebar would be a better option as it gives you a more aerodynamic position.

Next, it’s important to ensure that your brakes are well-maintained and working properly. Without properly functioning brakes, you risk injury and accidents. Regular maintenance of your brakes is necessary to keep them in top condition.

This can include adjusting the brake cables and brake pads, cleaning the braking surface, and checking for any wear and tear. Remember, your safety is paramount, and it’s better to be safe than sorry.

Once you’ve installed the handlebars and brakes, it’s time to move on to the next step and install the drivetrain.

Install the Drivetrain

Now that the frame’s assembled, it’s time to move onto the drivetrain. This involves selecting the right components for your bike, attaching the crankset and pedals, and installing the chain and rear cassette.

First, consider the terrain you’ll be riding on and your personal preference for gearing when choosing your drivetrain components.

Then, attach the crankset and pedals, making sure they’re securely tightened.

Finally, install the chain and rear cassette, ensuring they’re properly aligned and tensioned for smooth shifting and efficient power transfer.

Choosing Your Drivetrain Components

Selecting the right drivetrain components is crucial in building a four-wheel bicycle. One of the first things to consider is your budget versus the level of performance you desire. There are many different brands and types of drivetrain components available at different price points, so it’s important to do your research and find the best combination of affordability and quality.

Keep in mind that the drivetrain components you choose will affect the overall weight of your four-wheel bicycle, as well as its efficiency and ease of use. Another important factor when choosing drivetrain components is compatibility with your chosen frame design. Make sure you select components that will fit and work well with your frame, and that the gearing is appropriate for your intended use.

Some common drivetrain components include derailleurs, shifters, cassettes, and chains. It’s important to choose high-quality components that will last and perform well, as replacing individual components can be costly and time-consuming.

With the right drivetrain components in place, you’ll be ready to move on to attaching the crankset and pedals.

Attaching the Crankset and Pedals

Attaching the crankset and pedals requires a careful approach to ensure optimal performance and stability of the bike. First, it’s important to consider pedal placement and crank arm length. Pedal placement determines the angle at which your foot engages the pedal, and can affect your comfort and pedaling efficiency. Generally, the ball of your foot should be over the pedal axle, and the pedal should be level with the ground.

Crank arm length refers to the distance between the center of the pedal axle and the center of the bottom bracket spindle. Longer crank arms provide more leverage and are often used by taller riders, while shorter crank arms are more suitable for shorter riders or those with knee issues. Once you’ve chosen the appropriate crankset and pedals, it’s time to install them onto the bike frame. Refer to the manufacturer’s instructions for specific details on installation, as the process can vary depending on the components you’ve chosen.

As you attach the crankset and pedals, you’ll need to pay close attention to the torque specifications for each component to ensure they’re tightened to the appropriate level. Keep in mind that over-tightening can damage the components, while under-tightening can cause them to loosen during use. Once you’ve successfully attached the crankset and pedals, you can move on to installing the chain and rear cassette.

Installing the Chain and Rear Cassette

Once the crankset and pedals are securely attached, it’s time to proceed with the installation of the chain and rear cassette.

Chain maintenance is crucial for the longevity and smooth operation of your four-wheel bicycle. Before installing the chain, you should clean it thoroughly and lubricate it properly according to the manufacturer’s instructions. This will ensure that the chain will operate smoothly and quietly, and will also protect the chain from rust and wear.

Choosing the right cassette size is also important. The cassette size will determine the range of gears available, and will affect the overall performance of your four-wheel bicycle. The right cassette size will depend on your riding style, terrain, and personal preference. It’s recommended to consult with a professional bicycle mechanic or do some research to determine the optimal cassette size for your four-wheel bicycle.

Once you have installed the chain and cassette, you’re ready to test and adjust your four-wheel bicycle to ensure optimal performance on the road or trail.

Test and Adjust Your Four-Wheel Bicycle

Now that the drivetrain’s installed, it’s time to test and adjust your four-wheel bicycle.

To ensure optimal performance and safety, conduct a series of safety checks before taking it out for a ride. Test the brakes, ensure all bolts are tightened, and check for any loose or damaged parts.

Once you’ve ensured the safety of your bike, make adjustments to the seat, handlebars, and pedals for optimal comfort and performance.

Safety Checks

First things first, you gotta check all the nuts and bolts to make sure they’re tight and won’t come loose while you’re riding like a bat outta hell – you don’t want any unnecessary accidents happening. This is the importance of inspection and maintenance precautions before riding your four-wheel bicycle.

It’s crucial to check the brakes and ensure they’re functioning properly. The brake pads should be in good condition and not worn out.

Additionally, you must wear common safety gear and equipment such as a helmet, reflective clothing, and gloves. It’s also important to make sure the lights and reflectors are working correctly before you hit the road.

All these safety checks will ensure a safe and enjoyable ride. With all the necessary safety checks in place, the next step is to make adjustments for optimal performance.

Making Adjustments for Optimal Performance

To achieve optimal performance on your quadricycle, you’ll need to make adjustments to the seat height, handlebar position, and pedal alignment.

First, adjust the seat height so that your legs are almost fully extended when the pedals are at their lowest point. This will ensure that you’re able to generate maximum power with each pedal stroke.

Next, adjust the handlebar position so that it’s comfortable and allows you to maintain a relaxed grip while riding.

Finally, adjust the pedal alignment so that your feet are parallel to the ground when the pedals are at their lowest point. This will help to prevent knee pain and ensure that you’re able to pedal efficiently.

Adjustment techniques can vary depending on the specific quadricycle model you’re working with. However, some general troubleshooting tips include checking that all bolts and screws are tightened properly, ensuring that the chain is properly lubricated and tensioned, and checking that the brakes are functioning properly.

If you’re experiencing any issues with your quadricycle, it’s important to address them promptly to ensure that you’re able to ride safely and comfortably. With a little bit of patience and attention to detail, you can make the necessary adjustments to your quadricycle and enjoy a smooth and efficient ride.

Frequently Asked Questions

How much weight can a four-wheel bicycle carry?

Hold on tight, because my four-wheel bicycle can handle a hefty load. With a weight capacity of up to 600 pounds, it’s perfect for cargo transportation. Trust me, this machine is built to last.

What is the maximum speed a four-wheel bicycle can reach?

I have explored the limits of speed on a four-wheel bicycle and found that acceleration capabilities vary depending on terrain impact. Factors affecting load capacity include weight distribution on the four wheels.

Can a four-wheel bicycle be ridden in the rain or snow?

Yes, a four-wheel bicycle can be ridden in the rain or snow. However, riding comfort may be affected and maintenance requirements may increase. Proper care and maintenance are necessary to ensure safety and longevity of the bicycle.

Is it possible to add a motor to a four-wheel bicycle?

Adding a motor to a four-wheel bicycle has its pros and cons. Electric motors are eco-friendly, quiet, and require less maintenance. Gas-powered motors are more powerful but emit harmful gases. Choosing the right type depends on personal preference and intended use.

How long does it typically take to build a four-wheel bicycle?

Building a four-wheel bicycle can take anywhere from a few weeks to several months depending on the complexity and the availability of building materials and tools needed.

Conclusion

In conclusion, building a four-wheel bicycle was a challenging yet rewarding experience. It required precision and attention to detail at every step, from gathering the necessary tools and materials to designing and planning the bicycle. Assembling the frame and installing the drivetrain were the most time-consuming parts of the process, but with patience and determination, it all came together in the end.

As the famous adage goes, "Rome wasn’t built in a day."Similarly, building a four-wheel bicycle requires time, effort, and dedication. It’s important to take your time and not rush the process to ensure that every component is installed correctly.

Testing and adjusting your four-wheel bicycle is also crucial to ensure that it functions properly and is safe to ride.

Overall, building a four-wheel bicycle is a worthwhile endeavor that requires technical skill and precision. With the right tools, materials, and mindset, anyone can take on this challenge and create their own unique ride. So, if you’re up for the challenge, put on your safety gear and get ready to pedal your way to success!