Searching for an affordable method to enhance your bicycle’s speed and power? Discover the solution by constructing a motorized bicycle using a weedeater engine.

With a few basic tools and some know-how, you can transform your ordinary bicycle into a high-speed machine that will turn heads on the road.

The first step in building your motorized bicycle is selecting the right weedeater motor. Look for a motor with a displacement of 25cc or greater, as this will provide the power you need to propel your bicycle forward. You’ll also want to make sure the motor is in good condition and has been well-maintained, as this will ensure reliable performance on the road.

Once you have your weedeater motor in hand, it’s time to prepare your workspace and get started on the build.

Key Takeaways

- Choose a weedeater motor with a displacement of 25cc or greater for power

- Prioritize safety by choosing a safe and secure work area, wearing protective gear, and avoiding common safety hazards

- Install clutch for power transfer between engine and drivetrain, and add chain tensioner to keep chain from slipping

- Conduct performance testing to evaluate motor performance and fine-tune for optimal running, while keeping safety precautions in mind.

Select the Right Weedeater

You’ll want to make sure you pick the right weedeater for this project, so don’t just grab the first one you see at the hardware store.

There are several factors to consider when choosing a weedeater for your motorized bicycle, such as the size of the engine, the type of fuel it uses, and the weight of the machine.

A weedeater with a larger engine will provide more power, but it will also be heavier and more difficult to mount onto your bike.

On the other hand, a weedeater with a smaller engine may not provide enough power to propel your bike forward.

Another important factor to consider is weedeater maintenance.

You’ll want to choose a weedeater that is easy to maintain and repair, as it will be exposed to a lot of wear and tear while attached to your bike.

Look for a weedeater with easily accessible parts, such as spark plugs and air filters, and make sure that replacement parts are readily available.

With these factors in mind, you can select a weedeater that is appropriate for your project and begin preparing your workspace.

Prepare Your Workspace

Before starting to work on your motorized bicycle weedeater motor, it’s important to prepare your workspace properly. This involves gathering all the necessary tools, choosing a safe and secure work area, and taking safety precautions to avoid accidents.

To ensure a successful and safe project, make sure you have all the tools you need and create a workspace that minimizes risk and maximizes efficiency.

Gathering Necessary Tools

Gotta have those tools if you want to turn that weedeater into a motorized bicycle! Before starting any project, it is essential to gather all the necessary tools to ensure a smooth and successful build. For this project, you will need a variety of tools, including hand tools, power tools, and safety equipment.

To help you get started, here is a table of the necessary tools and equipment for the project. Keep in mind that the specific tools needed may vary depending on the weedeater motor type and the specific build requirements.

| Tools and Equipment | Description |

|---|---|

| Socket set | Used to tighten and loosen nuts and bolts |

| Screwdrivers (Phillips and flathead) | Used to tighten and loosen screws |

| Pliers | Used to grip and manipulate objects |

| Wire cutters | Used to cut wires to the appropriate length |

| Welder | Used to weld metal parts together |

| Safety glasses | Protective eyewear to protect eyes from debris |

Now that you have all the necessary tools and equipment, the next step is to choose a safe and secure work area to begin building your motorized bicycle.

Choosing a Safe and Secure Work Area

When creating your DIY motorized bicycle weedeater motor, it’s essential to prioritize safety by selecting a secure and organized work area. Workspace organization is crucial to ensure that you can work efficiently and safely. Here are three items to consider when choosing a workspace:

-

Choose a well-ventilated area: A well-ventilated space will help you avoid inhaling harmful fumes and prevent heat buildup, reducing the risk of fire.

-

Identify potential hazards: Before setting up your workspace, identify all potential hazards such as sharp objects, tripping hazards, and flammable materials. Keep your workspace organized and clean to avoid potential hazards.

-

Ensure adequate lighting: Poor lighting can cause injuries and damage to your project. Ensure adequate lighting in your workspace by using bright lights or natural light sources.

Taking safety precautions is crucial when building a motorized bicycle weedeater motor. After choosing a safe and secure workspace, the next step is to take necessary safety measures to prevent accidents and injuries.

Taking Safety Precautions

To ensure your safety while working on your DIY project, you should take necessary precautions to prevent accidents and injuries. The first and most important step is to wear the appropriate protective gear.

For this particular project, you should wear eye protection, gloves, and long-sleeved clothing. This will protect you from flying debris, hot engine parts, and any spills or leaks of fuel or oil.

In addition to wearing protective gear, it’s important to be aware of common safety hazards to avoid. These include working with sharp tools, working with electricity, and working with flammable materials.

Always read the instructions carefully and follow them precisely. Make sure to keep your work area clean and organized, and never leave tools or materials lying around where they can cause tripping hazards.

By taking these precautions, you can ensure a safe and successful project. Now that you’re aware of the importance of safety, it’s time to attach the motor to the bicycle.

Attach the Motor to the Bicycle

Attaching the motor to your bicycle is a crucial step in transforming your weedeater motor into a motorized bicycle. Before proceeding, make sure to have the necessary tools at hand, including a wrench, screwdriver, and pliers. Once you have these, follow these steps to ensure a successful installation:

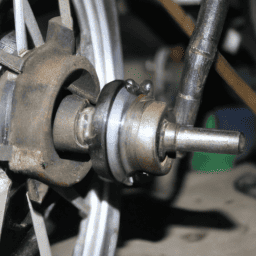

First, align the motor with the bicycle frame. Place the motor on the bicycle’s down tube and ensure that it is level and centered. Check that the motor’s chain is aligned with the bicycle’s rear sprocket. Adjust the position of the motor using spacers or washers until it is correctly aligned. Once the alignment is set, secure the motor in place using the mounting bracket provided.

Next, wire the connections between the motor and the bicycle’s electrical system. Refer to the manufacturer’s instructions for the specific wiring diagram. Connect the motor’s positive and negative wires to the battery, and the throttle to the handlebars. Finally, test the motor to ensure that it is running correctly.

Now that you have attached the motor to your bicycle and wired the connections, it’s time to make necessary modifications to ensure a safe and functional motorized bicycle.

Make Necessary Modifications

Now that you’ve attached the motor to your bicycle, it’s time to make some necessary modifications to ensure optimal performance.

First, you’ll need to adjust the carburetor and throttle to fine-tune the fuel-to-air ratio and control the engine’s speed.

Next, you’ll need to install a clutch to engage and disengage the engine from the bike’s drivetrain.

Finally, adding a chain tensioner will help keep the chain from slipping or coming off the sprockets, which can cause damage or accidents.

These modifications are crucial for a safe and efficient motorized bicycle.

Adjusting Carburetor and Throttle

Fine-tuning the carburetor and throttle is crucial for achieving optimal performance on your motorized weedeater bicycle. Here are three steps to help you optimize performance and troubleshoot any issues:

-

Adjust the air/fuel mixture: Locate the carburetor adjustment screws and turn them clockwise until they’re fully seated. Then, turn them counterclockwise 1.5 turns to get a good starting point. Start the engine and let it idle for a few minutes before turning the screws to adjust the air/fuel mixture. Turn the screw clockwise to make the mixture leaner and counterclockwise to make it richer. Keep adjusting until the engine runs smoothly and accelerates without hesitation.

-

Adjust the idle speed: Locate the idle speed screw and turn it until the engine is idling at the correct speed. The ideal speed for most weedeater motors is around 2000-3000 RPMs. If the engine idles too low, it may stall when you try to accelerate. If it idles too high, it can cause excessive wear on the engine and transmission.

-

Adjust the throttle cable: Make sure the throttle cable is properly adjusted so that the carburetor is opening fully when you twist the throttle. If the cable’s too loose, it can cause sluggish performance and make it harder to start the engine. If it’s too tight, it can cause the engine to rev too high and potentially damage the motor.

After fine-tuning your carburetor and throttle, the next step is installing a clutch.

Installing a Clutch

Next up, you’ll need to install a clutch to ensure smooth and efficient power transfer between the engine and the rear wheel. The clutch is responsible for engaging and disengaging the engine from the drive train. When the clutch lever is pulled in, the engine is disengaged from the drive train, allowing the bike to coast. When the lever is released, the clutch engages, transferring power to the rear wheel.

To install the clutch, start by removing the clutch cover and exposing the clutch assembly. Install the clutch pad and spring on the clutch drum, then replace the clutch cover. Make sure the clutch cable is adjusted properly, so the clutch lever has a smooth and consistent feel.

If you experience any issues with the clutch, there are a few troubleshooting techniques you can try. For example, if the clutch is slipping, it may be due to worn clutch pads or a loose clutch cable. Clutch maintenance is important to ensure proper function and longevity of the clutch system.

Now that the clutch is installed, you’ll need to add a chain tensioner to keep the chain tight and prevent it from falling off.

Adding a Chain Tensioner

To ensure your chain stays securely in place, you’ll need to add a chain tensioner to your setup. This device will help to keep your chain from slipping or coming off during operation.

Here are some tips to help you with the chain tensioner installation and maintenance:

-

First, ensure that you have the correct size chain tensioner for your bicycle and weedeater motor setup. This will depend on the size and type of chain you’re using, as well as the width of your motor mount.

-

Next, install the tensioner onto your motor mount, using the provided bolts or screws. Make sure that the tensioner is positioned correctly, so that it lines up with your chain and can apply pressure evenly.

-

Finally, adjust the tensioner so that it provides enough pressure to keep your chain in place, without causing it to bind or wear excessively. Check the tension regularly, and adjust as needed to maintain optimal performance.

With your chain tensioner installed and adjusted properly, you’re ready to move on to the next step of testing and adjusting your motorized bicycle setup.

Test and Adjust

Now it’s time to get your hands dirty and start testing and adjusting the motorized weedeater bicycle to ensure optimal performance. Performance testing is the process of evaluating the performance of your motorized bicycle weedeater motor. It’s important to fine tune the motor to make sure it’s running smoothly and efficiently. Here are some steps you can follow to test and adjust your motor:

| Test | Procedure |

|---|---|

| Compression Test | Remove the spark plug and insert a compression tester into the spark plug hole. Pull the starter cord and check the reading on the tester. The reading should be around 90 psi. |

| Idle Speed | Start the engine and let it warm up for a few minutes. Adjust the idle speed screw until the engine is idling smoothly. |

| Throttle Response | Rev the engine and check the throttle response. The engine should respond quickly and smoothly to changes in throttle position. |

After you’ve completed the tests, it’s time to fine tune the motor. Fine tuning involves adjusting the carburetor to ensure the air/fuel mixture is correct. A lean mixture will cause the engine to run hot and may cause damage, while a rich mixture will cause the engine to run poorly and waste fuel. Here’s how you can fine tune your motor:

| Adjustment | Procedure |

|---|---|

| Fuel Mixture | Locate the carburetor adjustment screws and turn them clockwise until they’re snug. Then, turn them counterclockwise 1 1/2 turns. Start the engine and let it warm up. Adjust the idle screw until the engine is idling smoothly. Then, adjust the fuel mixture screws until the engine is running smoothly at all throttle positions. |

| Spark Plug | Check the spark plug color. If it’s black or oily, the fuel mixture is too rich. If it’s white or gray, the fuel mixture is too lean. Adjust the fuel mixture screws accordingly. |

| Air Filter | Make sure the air filter is clean and free of dirt and debris. A dirty air filter can cause the engine to run poorly. |

By following these steps, you can ensure that your motorized bicycle weedeater motor is running smoothly and efficiently. Remember to always wear protective gear and follow safety precautions when working with engines.

Frequently Asked Questions

What tools and materials are required for the project?

For the project, you will need to make a tools selection that includes a drill, wrenches, pliers, and a socket set. Material preparation involves sourcing a weedeater motor, a bicycle frame, pulleys, and a chain.

How long does it typically take to complete the project?

Building a motorized bicycle weedeater motor can take anywhere from a few hours to a few days, depending on your experience and skill level. It’s important to take safety precautions and weigh the pros and cons before embarking on this project.

What is the maximum speed that can be achieved with a motorized weedeater bicycle?

To optimize performance of a motorized weedeater bicycle, consider the top speed and acceleration. Safety gear and precautions must be taken before taking the bike on the road. The maximum speed varies depending on the model and modifications made.

Are there any legal restrictions or requirements for riding a motorized bicycle on public roads?

Before hitting the road with your motorized bicycle, make sure to comply with licensing requirements and safety regulations. Keep in mind that these laws vary by state, so do your research.

How often does the motor require maintenance and what kind of maintenance is necessary?

To ensure optimal performance and safety, the frequency of maintenance for a motorized bicycle is crucial. Common issues to look out for include adjusting the carburetor, cleaning the air filter, and checking the spark plug. Regular oil changes and chain lubrication are also necessary.

Conclusion

Congratulations! You’ve successfully built a motorized bicycle with a weedeater motor. By following the steps in this guide, you’ve transformed a regular bicycle into a powerful and efficient machine.

One interesting statistic to note is that motorized bicycles are becoming increasingly popular in urban areas. In fact, according to a study by the National Association of City Transportation Officials, the number of trips taken on motorized bicycles in the United States increased by 25% from 2016 to 2017. This shows that more and more people are recognizing the benefits of motorized bicycles, such as their cost-effectiveness, eco-friendliness, and convenience.

As you take your new motorized bicycle for a spin, remember to wear a helmet and follow all traffic laws.

You now have a unique and fun mode of transportation that is sure to turn heads and make your daily commute more enjoyable.

Happy riding!