In the realm of electric bicycles, the rotor functions as the pulsating heart, and the permanent magnets housed within serve as the vital force propelling the vehicle forward.

But what happens when those magnets start to lose their power? Fear not, for I am here to guide you through the process of replacing those magnets and restoring your electric bike to its former glory.

With the right tools, a little patience, and a touch of technical know-how, you’ll soon be back on the road, feeling the exhilarating power of your newly revamped electric ride.

Key Takeaways

- Permanent magnets create a magnetic field in the rotor

- Electric motors with permanent magnets have higher efficiency and power density

- Properly dispose of old magnets through recycling centers or specialized companies

- Handle magnets with caution to avoid attracting metal objects or pinching fingers

Understand the Function of Permanent Magnets in the Rotor

You need to understand how the permanent magnets in the rotor function. The function of permanent magnets in electric motors is crucial for their operation. These magnets are strategically placed on the rotor to create a magnetic field that interacts with the stator coils, resulting in the generation of rotational motion.

By utilizing permanent magnets, electric motors can achieve higher efficiency and power density compared to other types of motors. The advantages of using permanent magnets in rotor design include reduced energy losses, improved torque output, and compact size.

To replace the permanent magnets on the rotor of an electric bike, it is essential to gather the necessary tools and materials.

Gather the Necessary Tools and Materials

First, gather all the tools and materials needed for the task. When replacing permanent magnets on the rotor of an electric bike, it’s crucial to select suitable replacement magnets. Look for magnets that have the same dimensions and magnetic strength as the original ones. This will ensure proper functioning of the bike’s motor.

Additionally, it’s important to properly dispose of the old magnets. Check with local recycling centers or contact specialized companies that handle magnet disposal.

Once you have gathered the necessary tools and materials, you can proceed to disconnect the power source and remove the rotor. This will be discussed in the subsequent section.

Disconnect the Power Source and Remove the Rotor

To begin, make sure the power source is disconnected and proceed to remove the rotor.

Here are the steps to follow:

-

Locate the power switch or unplug the bike from the electrical outlet to disconnect the power source. Safety is paramount during this process.

-

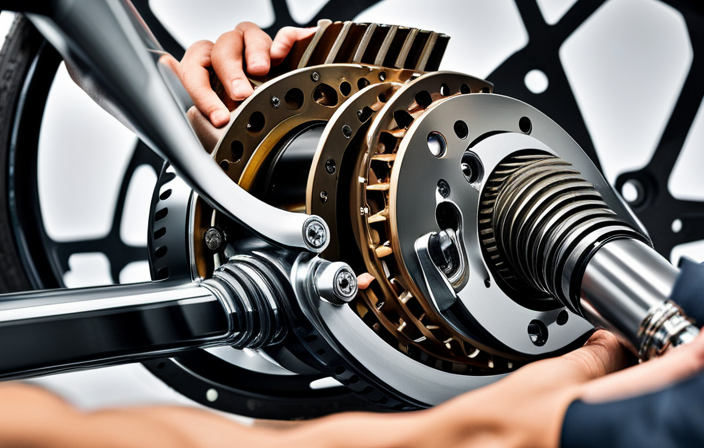

Use a wrench or socket set to loosen the bolts or screws securing the rotor to the bike’s hub. Carefully remove the rotor, ensuring not to damage any surrounding components.

-

Take note of the position and orientation of the rotor for reassembly later. This will help maintain the balance and performance of the bike.

-

Place the removed rotor in a safe and clean area, away from any potential damage or contamination.

Now that the rotor is removed, we can safely proceed to the next section on how to remove the old permanent magnets.

Safely Remove the Old Permanent Magnets

Once the power source is disconnected and the rotor has been removed, it is important to safely remove the old magnets without causing any damage. When dealing with magnet replacement techniques, there are potential risks that need to be considered. To ensure a successful replacement, follow these steps carefully. First, use a non-magnetic tool to gently pry off the old magnets from the rotor. Avoid using excessive force, as this could lead to damage. Place the removed magnets in a secure container to prevent them from getting lost or causing harm. It is crucial to handle the magnets with caution, as they can attract metal objects and pinch fingers. Take your time and be precise during this process to avoid any mishaps. Once the old magnets are safely removed, it’s time to clean and prepare the rotor for new magnets, ensuring a smooth transition for optimal performance.

Clean and Prepare the Rotor for New Magnets

To clean and prepare the rotor for new magnets, you’ll need to carefully remove any residual adhesive or debris left behind. This is a crucial step in the magnet replacement process to ensure proper adhesion and functionality of the new magnets.

Start by gently scraping off any adhesive using a plastic scraper or a soft brush. Take care not to damage the rotor surface. Once the adhesive is removed, use a cleaning solvent to dissolve any remaining residue. Isopropyl alcohol or acetone can be effective options for this task. Apply the solvent to a clean cloth and gently wipe the rotor surface until it is completely clean. Make sure to let it dry thoroughly before proceeding to the next step of installing the new permanent magnets.

Now that the rotor is clean, we can move on to the next section about installing the new permanent magnets.

Install the New Permanent Magnets

Now you can begin installing the new magnets onto the clean rotor surface. This is a crucial step in the magnet replacement process.

Make sure you have the correct replacement magnets that match the specifications of your electric bike’s rotor.

Start by applying a thin layer of adhesive to the back of each magnet. Then, carefully position the magnets onto the rotor surface, ensuring proper alignment and placement.

Be sure to follow any specific instructions provided by the manufacturer regarding magnet orientation or polarity.

Once all the magnets are in place, allow the adhesive to dry and bond securely. This will ensure that the magnets stay firmly attached to the rotor during operation.

In the subsequent section about ensuring proper alignment and placement, we will discuss the final steps to complete the magnet replacement process.

Ensure Proper Alignment and Placement

To ensure the magnets stay securely attached during operation, it is important to carefully align and position them on the rotor surface. Proper alignment techniques are crucial in achieving optimal performance and preventing any potential issues.

Start by identifying the correct polarity of each magnet and match it with the corresponding markings on the rotor. Use a reliable alignment tool, such as a magnetic field indicator, to ensure precise placement.

Troubleshooting common issues, such as magnet misalignment or uneven spacing, can be resolved by double-checking the alignment and making necessary adjustments.

Once the magnets are properly aligned, it is time to reassemble the rotor and reconnect the power source, ensuring a smooth transition into the next step of the process.

Reassemble the Rotor and Reconnect the Power Source

Once the magnets are properly aligned, it’s time to put the rotor back together and reconnect the power source. Reassembling the rotor requires careful attention to detail and the use of specific techniques.

Here are some steps to follow:

- Begin by placing the rotor back onto the axle, ensuring that it sits securely.

- Next, reattach any screws or bolts that hold the rotor in place, making sure they are tightened properly.

- Once the rotor is securely in place, reconnect the power source by attaching the wires to their respective terminals.

- Double-check all connections to ensure they are tight and secure.

Troubleshooting common issues during reassembly is essential. Look out for any loose connections or damaged wires, and address them promptly.

Finally, transition into the next section by mentioning the importance of testing the electric bike for proper functioning.

Test the Electric Bike for Proper Functioning

After reassembling the rotor and reconnecting the power source, it is crucial to test the electric bike to ensure optimal performance. Testing the bike allows you to troubleshoot any issues and make necessary adjustments.

Start by turning on the power and observing the response of the bike. Check if the motor engages smoothly and if the bike accelerates and decelerates properly. Pay attention to any strange noises or vibrations, as they could indicate an underlying problem.

Test the bike on different terrains and at various speeds to ensure consistent performance. Additionally, check if the brakes are functioning correctly and if all the electrical components are working as intended.

By thoroughly testing the electric bike, you can identify and address any potential issues promptly. This will help maintain and regularly inspect the permanent magnets for longevity.

Maintain and Regularly Inspect the Permanent Magnets for Longevity

Make sure you regularly inspect and maintain the magnets to ensure they last longer. Here are some important tips to increase the lifespan of your permanent magnets:

-

Cleanliness: Keep the magnets clean and free from debris or dust that can affect their performance.

-

Avoid overheating: Excessive heat can demagnetize the magnets, so make sure they aren’t exposed to high temperatures for prolonged periods.

-

Proper storage: Store the magnets in a cool, dry place to prevent any moisture damage.

-

Check for cracks or chips: Inspect the magnets for any signs of cracks or chips that can weaken their magnetic properties.

-

Avoid strong impacts: Protect the magnets from strong impacts or collisions that can cause damage.

Regularly inspecting the magnets and following these maintenance steps will help extend their lifespan, ensuring optimal performance of your electric bike.

Frequently Asked Questions

How do permanent magnets work in an electric bike rotor?

Permanent magnets in an electric bike rotor generate electricity by creating a magnetic field that interacts with the stator windings, inducing an electric current. This current powers the bike’s motor, increasing efficiency and providing propulsion.

What tools and materials are needed to replace permanent magnets on an electric bike rotor?

To replace permanent magnets on an electric bike rotor, you’ll need a few essential tools: a screwdriver, pliers, and possibly a heat gun. Additionally, gather the necessary materials such as replacement magnets and adhesive.

How do you disconnect the power source and remove the rotor?

To disconnect the power source and remove the rotor, first ensure the electric bike is turned off. Then, locate and disconnect the power cable from the battery. Next, use the appropriate tools to remove the bolts securing the rotor to the bike.

What is the proper way to remove the old permanent magnets safely?

Proper removal techniques and safety precautions are essential when taking out old permanent magnets. Like carefully extracting a delicate pearl from its shell, I’ll guide you through the process, ensuring precision and protection.

How do you clean and prepare the rotor for the installation of new magnets?

To clean and prepare the rotor for magnet installation, I begin by removing any debris or residue using a clean cloth and mild solvent. Then, I carefully inspect the surface for any damage or irregularities that may affect the magnet’s performance.

Conclusion

In conclusion, replacing the permanent magnets on the rotor of an electric bike is a task that requires knowledge, precision, and the right tools. By understanding the function of these magnets and following the steps outlined in this article, you can successfully replace them and ensure the proper functioning of your bike.

Just like how a well-oiled machine relies on all its parts working in harmony, the magnets on the rotor play a crucial role in generating power and propelling your bike forward. So, take care of them, inspect them regularly, and enjoy the smooth ride they provide.