Protective coatings help you extend the life of your surfaces by acting as a tough barrier against corrosion, wear, and environmental damage. They prevent rust, fading, cracking, and peeling, especially in harsh conditions like saltwater or chemicals. Modern coatings incorporate advanced materials to guarantee long-lasting protection, even in extreme weather. Choosing the right coating depends on your specific environment, and proper application is essential for maximum durability. Keep exploring to discover how you can best protect your assets.

Key Takeaways

- Provide a durable barrier against corrosion, wear, moisture, and chemicals to extend surface lifespan.

- Offer environmental durability, resisting UV radiation, extreme weather, and temperature fluctuations.

- Require proper surface preparation and application to ensure maximum adhesion and long-term effectiveness.

- Incorporate advanced technologies like polymers and UV stabilizers for enhanced protection in harsh conditions.

- Select coatings tailored to specific environmental challenges, such as saltwater or industrial chemical exposure.

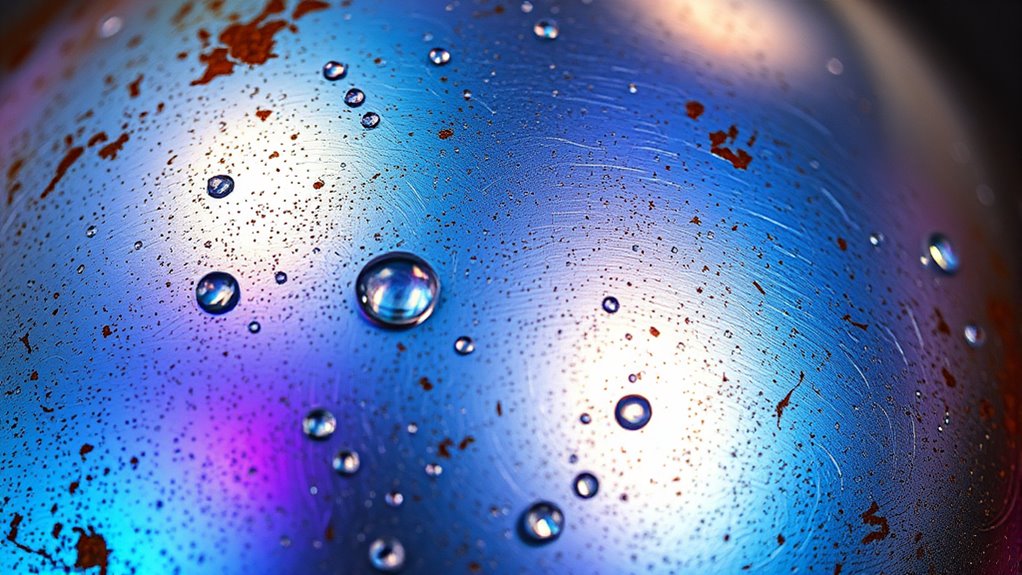

Protective coatings play an essential role in extending the lifespan of surfaces by providing a barrier against corrosion, wear, and environmental damage. When you apply the right coating, you prevent rust from forming on metal surfaces, which is vital in industrial, marine, or outdoor settings. Corrosion resistance is a key benefit because it shields materials from moisture, salts, and chemicals that can cause deterioration. By creating a tough, impermeable layer, you reduce the risk of structural failure and costly repairs over time.

Environmental durability is equally important. You need coatings that withstand extreme weather conditions, UV radiation, and temperature fluctuations without breaking down. For example, if you’re protecting outdoor equipment or infrastructure, your coating must resist fading, cracking, or peeling when exposed to harsh sunlight or heavy rain. This durability guarantees your surfaces stay intact and look good longer, saving you money and effort on maintenance.

Choosing the right protective coating depends on understanding the specific environment your surface faces. For instance, in saltwater environments, you might opt for a coating with enhanced corrosion resistance to prevent salt-induced rust. In industrial settings with chemical exposure, a chemically resistant coating becomes necessary. In all cases, the goal is to create a barrier that stays intact for years, providing continuous protection against environmental factors.

Applying a protective coating isn’t just about the initial layer; it’s about ensuring long-term performance. Proper surface preparation is vital. You need to clean and prime the surface thoroughly so the coating adheres properly, maximizing its effectiveness. Skipping these steps can lead to premature failure, exposing your surfaces to corrosion and environmental damage. Once applied correctly, a high-quality coating will form a seamless shield that protects against moisture ingress, chemical attack, and physical wear.

Moreover, advancements in coating technology have led to products that combine both corrosion resistance and environmental durability in one solution. These coatings often contain specialized polymers, corrosion inhibitors, or UV stabilizers, making them versatile for different applications. Whether you’re coating pipes, machinery, or building exteriors, selecting a coating with these attributes ensures your surfaces remain protected longer, even under tough conditions. Additionally, selecting the appropriate coating involves understanding the growing and harvesting conditions of nearby materials, as environmental factors can influence coating performance and longevity.

Frequently Asked Questions

How Long Do Protective Coatings Typically Last?

Protective coatings usually last between 2 to 10 years, depending on durability factors like exposure to weather, UV rays, and chemical contact. The coating lifespan varies based on the quality of materials used, application methods, and maintenance. To maximize durability, guarantee proper surface preparation and regular upkeep. Keep in mind that high-quality coatings tend to have a longer lifespan, providing better protection over time.

Are Protective Coatings Environmentally Friendly?

Protective coatings can be environmentally friendly if you choose eco-friendly materials and biodegradable options. These coatings reduce harmful emissions and minimize environmental impact. You should look for products labeled as non-toxic, water-based, or made from sustainable resources. By selecting these environmentally conscious options, you help safeguard the planet while maintaining your surfaces’ durability. Always check product labels and manufacturer information to ensure you’re making eco-friendly choices for your protective coatings.

Can Protective Coatings Be Applied to Existing Surfaces?

Yes, you can apply protective coatings to existing surfaces. First, guarantee proper surface preparation by cleaning, sanding, or etching to remove dirt, grease, and loose materials. This step enhances coating adhesion and improves coating durability. Once prepared, apply the coating evenly, following manufacturer instructions. This process prolongs the surface’s lifespan, resists damage, and maintains its appearance, making it a practical solution for maintaining and extending the life of your surfaces.

What Maintenance Is Required for Protective Coatings?

You need to regularly inspect your protective coatings to guarantee their durability. Start with surface preparation by cleaning and repairing any damage, which helps maintain adhesion. Then, perform coating inspections to identify signs of wear or deterioration. Reapply or touch up the coating as needed, especially after harsh weather or heavy use. Proper maintenance prolongs coating life, keeps surfaces protected, and prevents costly repairs down the line.

How Do I Choose the Right Coating for My Needs?

To choose the right coating, you need to consider surface preparation and coating durability. First, assess your surface’s material and condition, ensuring it’s clean and properly prepared. Then, evaluate the durability needed for your environment—whether it’s resistance to corrosion, weather, or wear. Select a coating designed for those conditions, balancing application ease and long-term performance. This way, you’ll ensure your protective coating effectively meets your specific needs.

Conclusion

In your pursuit of preservation, prioritize protective coatings that prevent pitting, peeling, and deterioration. By choosing the best barrier, you bolster your surfaces against the brutal blows of nature and time. Remember, diligent defense delivers durability, dignity, and distinction. Stay steadfast, select smart coatings, and secure your surfaces’ strength and splendor. Protecting your property isn’t just possible; it’s powerful—so persist, protect, and preserve with purpose.