When working with small components and delicate electronics, you need a torque screwdriver that offers precise control and reliable performance. Look for models with micro-adjustments, low torque ranges (like 0.3 Nm), and ergonomic designs that fit tight spaces comfortably. Digital versions with clear displays and preset features help prevent over-tightening and guarantee accuracy. Choosing the right type and features can improve your work quality—discover more about selecting the best torque screwdriver for your needs.

Key Takeaways

- Ensure the torque screwdriver provides precise, adjustable torque control for delicate electronic components.

- Use models with micro-adjustments and low torque ranges (as low as 0.3 Nm) for sensitive work.

- Select ergonomic, compact tools with quick bit-changing features for efficiency in tight spaces.

- Prefer digital or electronic screwdrivers with digital displays for accurate torque monitoring and recording.

- Verify calibration and use torque limiters to prevent over-tightening of small, fragile parts.

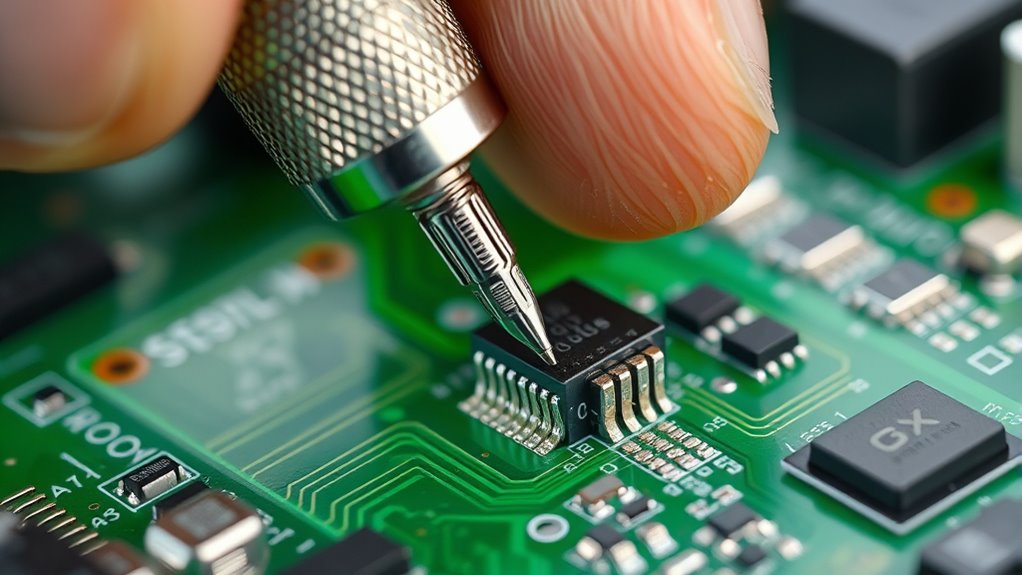

Understanding the Role of Torque Screwdrivers in Component Assembly

Understanding the role of torque screwdrivers in component assembly is essential because they help guarantee that each connection receives the correct amount of torque. An adjustable torque screwdriver allows you to set the precise torque needed for specific components, ensuring consistency across large production runs. Proper use prevents damage or loosening, which can compromise safety and reliability. These screwdrivers are available in various models, including electronic and micro-precision types, suitable for sensitive electronic parts. By controlling torque accurately, you reduce errors and rework, ultimately saving time and costs. Incorporating adjustable torque screwdrivers into your workflow enhances the quality and integrity of assembled components, ensuring they meet engineering standards and perform reliably over time.

Types of Torque Screwdrivers Suitable for Small Parts

When working with small parts, you’ll want torque screwdrivers that offer precise control and consistent results. Look for models with adjustable or fixed low torque ranges to handle delicate tasks safely. Additionally, choosing tools with compact, ergonomic designs helps you work comfortably and accurately in tight spaces. Incorporating professional equipment ensures high-quality results and durability for detailed component work. Emphasizing precise control is essential for avoiding damage to sensitive components and achieving the best assembly quality. Moreover, selecting screwdrivers with accurate torque settings helps prevent over-tightening or stripping tiny fasteners. For optimal performance, consider tools that are compatible with specialized bits designed for small fasteners. Using a torque screwdriver with consistent torque output can further improve accuracy and reduce the risk of component damage.

Precision in Small Parts

For working with small components, selecting the right torque screwdriver is crucial to guarantee precise assembly without damaging delicate parts. A Torque Screwdriver Set designed for precision in small parts offers micro torque ranges as low as 0.3 Nm or 1.2 in-lb, ideal for sensitive electronics and tiny fasteners. Fixed torque models ensure consistent force, reducing over-tightening risks. ESD-safe screwdrivers help prevent static damage during electronic assembly. Tip sizes like Torx T8, T10, and T15 are commonly used for small fasteners, providing secure engagement. Digital torque screwdrivers with ±2% accuracy and quick bit-changing features enable repeatable, precise torque application. Incorporating calibration ensures ongoing accuracy and consistent torque application in your work. Proper cleaning and maintenance of your tools can further enhance their lifespan and performance, ensuring reliable results over time. Utilizing appropriate torque ranges is essential for safeguarding delicate electronic components from damage. Using the appropriate filtration can further protect sensitive electronic components from debris during assembly, enhancing overall reliability.

Suitable for Delicate Tasks

Selecting the right torque screwdriver for delicate tasks involves choosing models designed specifically for small, sensitive components. You need a tool with torque limiting features that prevent over-tightening. Pre-set torque screwdrivers, like those with a full range from 0.3 Nm, ensure you apply the right torque without guesswork. For electronics, ESD-safe models such as WR074788 are ideal. Adjustable screwdrivers, like the Wera WR074700, let you fine-tune micro settings for tiny parts. When the torque is reached, the screwdriver provides tactile or visual feedback, preventing damage. Understanding torque limits is essential for proper assembly and avoiding component damage. Proper calibration and torque control help ensure consistent results. Here’s a quick overview:

| Type | Key Feature | Suitable For |

|---|---|---|

| Fixed torque | Consistent, low-range torque | Small, precise components |

| ESD-safe | Static-free, delicate electronics | Sensitive electronics |

| Adjustable | Micro settings, fine-tuning | Tiny parts requiring right torque |

| High-precision digital | ±2% accuracy, full range | Critical delicate assembly tasks |

Using the appropriate type of torque screwdriver can help protect delicate components from damage during assembly, especially when considering the cultural heritage associated with traditional craftsmanship that emphasizes precision and care. Additionally, selecting tools with calibration features ensures ongoing accuracy over time.

Compact and Ergonomic Design

Compact and ergonomic torque screwdrivers are essential tools for working in tight spaces and on small parts. These tools are ergonomically designed to enhance comfort and reduce user fatigue during detailed tasks. Typically measuring less than 8 inches, they allow for precise handling in confined areas. Many feature lightweight, balanced bodies with non-slip grips, making extended work easier and more comfortable. Adjustable torque settings, often ranging from 5-25 in-lb or 0.3-3 Nm, provide accurate control for delicate assemblies. Some models incorporate micro-scale dials or digital displays for easy, precise adjustments. Their small tip sizes, like Torx T8, T10, or 4.0 mm hex, and slim profiles are perfect for accessing tiny screws in electronics and miniature components. Additionally, Kia Tuning practices emphasize precision and control, which are crucial when working with sensitive parts. Moreover, the trustworthiness of brands such as Patchology highlights the importance of reliable tools and products to ensure consistent quality and performance. The design considerations also ensure that these screwdrivers are suitable for organic and sustainable manufacturing processes, aligning with eco-friendly practices.

Key Features to Consider When Selecting a Torque Screwdriver

When choosing a torque screwdriver, you need to prioritize accuracy and precision to guarantee consistent results. Consider the range and settings to match your specific components, especially delicate electronics. Ease of use, including intuitive adjustments and calibration, is also vital for maintaining efficiency and reliability. Additionally, selecting a torque screwdriver with quality construction can ensure durability and long-term performance. Ensuring the tool has calibration features helps maintain measurement accuracy over time, which is essential for precise work. Incorporating ergonomic design can also reduce fatigue during extended use and improve overall handling.

Accuracy and Precision

How do you guarantee consistent and accurate torque application when working with delicate components? The key is choosing a torque screwdriver with high accuracy and precision. Look for models offering ±2% accuracy, ensuring reliable torque delivery every time. Digital screwdrivers with LED displays let you monitor real-time torque, reducing errors. Adjustable models with micro-adjustments enable fine-tuning, ideal for sensitive work. Always verify calibration certificates and select tools meeting standards like ASME B107.300 to ensure long-term reliability. A well-designed clutch mechanism and clear, easy-to-read scales help prevent over-tightening. Here’s a quick overview:

| Feature | Benefit | Recommended Use |

|---|---|---|

| High accuracy (±2%) | Consistent torque application | Delicate component assembly |

| Digital display | Real-time measurement | Precise adjustments |

| Micro-adjustment | Fine-tuning torque | Sensitive parts |

| Calibration certificates | Reliability over time | Regular maintenance |

| Clear scales & clutch | Prevents over-tightening | General component work |

Range and Settings

Selecting the right torque screwdriver involves considering its adjustable range and specific settings to match your application needs. The torque value you require depends on the components you’re working with, so choosing a model with a suitable adjustable range is essential. Some screwdrivers offer a wide range from 0.3 Nm to 55 in-lbs, giving flexibility for various tasks. Fixed torque models provide consistent torque at specific settings, such as 0.3 Nm or 1.2 Nm, ideal for repetitive work. Sets that include multiple pieces cover broader torque ranges, like 1.2 to 3.0 Nm, increasing versatility. Also, consider tip sizes and drive types, which influence compatibility with different fasteners and components. Ensuring your torque screwdriver’s range and settings align with your application guarantees precise, reliable results.

Ease of Use

To guarantee accurate and efficient work, choosing a torque screwdriver with user-friendly features is essential. Look for torque screwdrivers with clear, easy-to-read digital or analog scales to ensure precise adjustments. Opt for models with simple adjustment mechanisms, like dials or torque keys, so you can quickly set the desired torque. Ergonomic grips and lightweight designs help reduce fatigue during extended use, increasing productivity. Choose tools with intuitive controls, such as push buttons or locking mechanisms, to prevent accidental adjustments. Quick-change bits or magnetic heads streamline bit switching, saving time and improving workflow. When selecting torque screwdrivers, prioritize ease of use to enhance accuracy, comfort, and efficiency in your component work.

Comparing Adjustable, Fixed, and Electronic Models

When choosing between adjustable, fixed, and electronic torque screwdrivers, understanding their key differences helps you pick the right tool for your needs. A screwdriver with adjustable settings offers versatile control, letting you set specific torque limits within a range, ideal for various tasks. Fixed torque screwdrivers are simple and reliable, providing a consistent torque value for repetitive work without adjustments. Electronic models elevate precision with digital displays, memory functions, and data tracking, making them perfect for quality control. They often support multiple units like Nm, in-lb, and ft-lb. Your choice depends on your application: adjustable screwdrivers suit diverse projects, fixed models excel in repetitive tasks, and electronic tools are best when accuracy and data recording are priorities.

Enhancing Precision With Digital Torque Screwdrivers

Digital torque screwdrivers markedly boost precision in component work by providing instant, highly accurate torque readings. With ±2% accuracy, they ensure consistent tightening, reducing errors. The digital displays make it easy to set, monitor, and record torque values, minimizing human mistakes. Many models support multiple units like Nm, in-lb, ft-lb, and kg-cm, fitting various component requirements. Advanced features such as preset memory recall and alarms help prevent over-tightening, protecting delicate parts during assembly.

| Feature | Benefit | Example Use |

|---|---|---|

| Digital display | Easy setting and monitoring | Precise torque adjustments |

| Multiple units support | Versatility for different components | Cross-industry compatibility |

| Memory functions | Quicker setup for common torque values | Increased efficiency |

Applications of Torque Screwdrivers in Electronics and Machinery

Torque screwdrivers play a crucial role in electronics and machinery by guaranteeing you apply the correct amount of torque to each fastener. In electronics, they help you tighten small screws precisely, preventing component damage and ensuring reliable connections. Using ESD-safe models protects sensitive parts from electrostatic discharge. For delicate electronic assemblies, adjustable torque screwdrivers with ranges like 0.3 Nm to 6 Nm let you set specific torque levels, reducing the risk of over-tightening. In machinery, these tools maintain consistent torque during assembly, minimizing wear and failure caused by over-tightening or under-tightening. High-precision torque screwdrivers ensure uniform fastening in manufacturing, which improves product quality and extends lifespan. Whether working on electronic devices or machinery, these tools are essential for achieving reliable, safe, and durable assembly results.

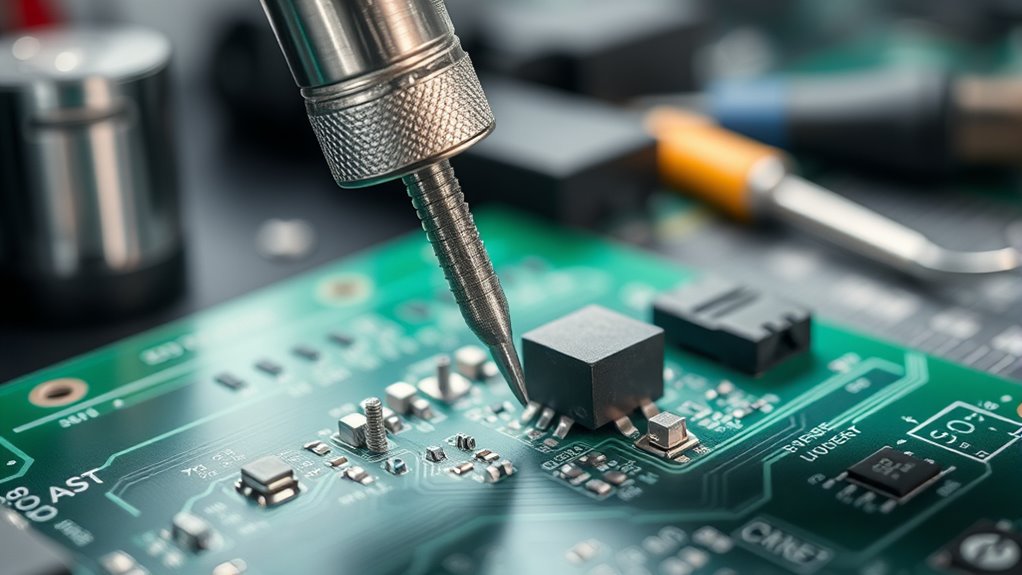

Tips for Proper Use and Maintenance of Torque Tools

Proper use and maintenance of torque screwdrivers are essential to guarantee accurate and reliable fastening. Always calibrate your torque screwdriver regularly, following the manufacturer’s instructions, to stay within ±2% accuracy. Use the correct tip size and drive type, like Torx T8 or HIOS, to prevent slippage and damage. Set the torque to the required level before starting work, and avoid changing it during operation to maintain consistency. After finishing, reset adjustable torque screwdrivers to their lowest setting to reduce stress on internal parts and preserve calibration. Store your tools properly in their case or designated area to protect the calibration mechanism and extend their lifespan. Following these tips ensures your torque screwdrivers perform reliably and last longer.

Choosing the Right Torque Range for Specific Component Tasks

Choosing the right torque range is essential to achieving accurate and safe fastenings for different components. Select a torque screwdriver with a range that slightly exceeds the maximum torque needed, like 0.3–3 Nm for delicate electronics, ensuring precise tightening without over-torquing. For small, sensitive parts such as circuit boards or microelectronics, opt for models with low torque ranges, around 0.3–1.0 Nm, to prevent damage. Use higher ranges, like 10–34 Ncm or 1.2–3.0 Nm, for components requiring moderate tightening, such as connectors or small mechanical fasteners. Confirm that measurement units (Nm, in-lb, Ncm) match industry standards or component specifications. When working with various components, consider adjustable sets that cover multiple ranges for flexibility and efficiency.

Frequently Asked Questions

Do You Really Need a Torque Screwdriver to Mount a Scope?

You might wonder if a torque screwdriver is necessary for mounting a scope. The truth is, using one guarantees you tighten the scope to the manufacturer’s recommended torque, usually between 15-25 in-lb. This prevents over-tightening, which can damage the mount or scope. With a torque screwdriver, you get consistent, precise results, reducing the risk of zeroing issues or scope failure over time, making it a smart investment.

What Is a Good Torque for Screwdriver?

Imagine you’re assembling delicate electronics; using the right torque makes all the difference. A good torque for screwdrivers varies by application—typically between 0.3 Nm and 6 Nm for small parts. For larger assemblies, 10 Nm or more works well. An adjustable torque screwdriver lets you set precise values, preventing damage. Always check manufacturer recommendations to guarantee you’re applying the correct torque and extending your component’s lifespan.

How Much Torque Can You Apply by Hand With a Screwdriver?

You can typically apply between 10 to 20 in-lb of torque by hand, depending on your strength and the task. For delicate components, it’s best to stay below 15 in-lb to prevent damage. Your hand’s strength varies, but most people find they can comfortably stay within this range. Using an adjustable torque screwdriver helps you maintain consistent, safe torque levels, especially for sensitive or precise work.

Do Torque Screwdrivers Need Calibration?

You might think torque screwdrivers stay accurate without calibration, but that’s not the case. They do need calibration to guarantee their torque settings remain precise over time. Regular calibration verifies that the tool applies the correct force, preventing under- or over-tightening. Many manufacturers recommend calibration at least once a year or after a specific number of uses, especially for critical or precision work. This keeps your work consistent and safe.

Are Torque Screwdrivers Used in High Torque Applications?

You might wonder if torque screwdrivers handle high torque. Generally, they don’t because they’re designed for low to medium torque ranges, usually up to 55 in-lbs. Using them for high torque tasks can damage the tool and compromise accuracy. For heavy-duty applications, you should opt for power tools or specialized torque wrenches that can safely and effectively handle higher force requirements.

Conclusion

So, next time you’re working with tiny components, remember that a torque screwdriver might just be the hero you didn’t realize you needed—until an over-tightened screw or a loose connection becomes your new nightmare. Ironically, the precision you seek depends on simple tools, but neglecting proper selection or care can turn those tiny screws into your biggest headache. Keep your tools and your workmanship tight—literally—and enjoy the peace of mind you deserve.