I recall the initial experience of purchasing a brand-new bike. The sheer range of choices presented to me was astonishing, and I was perplexed by the technical terms the sales representative employed.

One of the terms that particularly confused me was the name of the machine that powers the bicycle – what is it called? As it turns out, this machine is known as the bicycle drivetrain.

The bicycle drivetrain is made up of a series of components that work together to transfer the power generated by the rider’s legs to the wheels, propelling the bicycle forward. Understanding how the drivetrain works is essential for maintaining and upgrading your bicycle, as well as for selecting the right bike for your needs.

In this article, I’ll provide an overview of the components of the bicycle drivetrain, explain how they work together, and offer some tips for maintaining and upgrading your drivetrain.

Key Takeaways

- The bicycle drivetrain is made up of the chain, cassette, derailleur, and crankset.

- The chain transmits power from pedaling to the rear wheel and needs regular cleaning and lubrication to maintain efficiency.

- The cassette attaches to the rear wheel hub and allows for gear ratio adjustment, with different sizes customizing the bike for different riding styles.

- The derailleur shifts the chain laterally across the cassette, and precision and accuracy are important for riding up hills and down descents.

Components of the Bicycle Drivetrain

When it comes to the bicycle drivetrain, there are several key components that are essential for smooth and efficient riding. These include the chain, cassette, derailleur, and crankset.

As a cyclist, I understand the importance of each of these parts and how they work together to provide a seamless riding experience. From shifting gears to transferring power from the pedals to the wheels, the drivetrain is the heart of the bike and must be well-maintained for optimal performance.

Chain

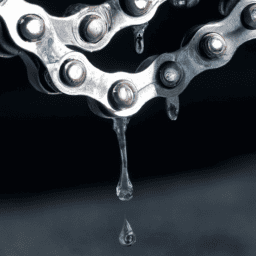

You can feel the power transfer as the chain connects the pedals to the back wheel of your bicycle, propelling you forward with each rotation. The chain, a crucial component of the bicycle drivetrain, is responsible for transmitting the power generated by the rider’s pedaling to the rear wheel. Chains come in various sizes and materials, but most commonly, they are made of steel. The chain’s durability and strength are essential because it is exposed to constant stress and strain during riding. Chain maintenance is crucial to ensure its longevity and proper functioning. Regular cleaning and lubrication are necessary to prevent rust, corrosion, and wear and tear.

To better understand the chain’s components, let’s take a look at the table below:

| Chain Material | Pros | Cons | Maintenance |

|---|---|---|---|

| Steel | Durable, affordable | Heavy, prone to rust | Regular cleaning and lubrication |

| Titanium | Lightweight, corrosion-resistant | Expensive | Regular cleaning and lubrication |

| Nickel-plated | Corrosion-resistant, aesthetically pleasing | Not as durable as steel | Regular cleaning and lubrication |

| Ceramic | Low friction, high durability | Expensive | Regular cleaning and lubrication |

Moving on to the next component of the bicycle drivetrain, the cassette plays a vital role in gear shifting.

Cassette

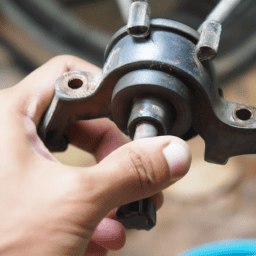

Now, the cassette is an essential part of your ride, and it’s important to understand how it works.

The cassette is a set of gears that attach to the rear wheel hub, allowing the rider to change the gear ratio and adjust the effort required to pedal.

It’s important to note that not all cassettes are compatible with all bikes, and it’s crucial to choose the right cassette for your bike.

One of the advantages of different cassette sizes is the ability to customize your bike to fit your riding style.

For example, a larger cassette with a wide range of gears is ideal for climbing steep hills, while a smaller cassette with fewer gears is better suited for flat terrain and faster speeds.

The important thing to remember is that the cassette needs to be compatible with your bike’s derailleur, which we will discuss in the next section.

Derailleur

If you want to shift gears smoothly and effortlessly on your ride, the derailleur is like a conductor, guiding the chain from one gear to another with precision and ease. The derailleur is a critical component of a bicycle’s shifting mechanism.

It is responsible for moving the chain from one gear to another by shifting the chain laterally across the cassette at the rear wheel. Bicycle gears are an essential part of any cyclist’s gear setup, and the derailleur is what enables us to use them effectively.

When you shift gears, the derailleur moves the chain from one gear to another by pushing and pulling it across the cassette. This movement is made possible by a series of springs and cables that connect the derailleur to the shifters on the handlebars. With the right combination of gears, you can ride up steep hills or fly down descents with ease, all thanks to the derailleur’s precision and accuracy.

Moving on to the next section, the crankset is another critical component that works in tandem with the derailleur to make your ride smooth and efficient.

Crankset

As a cyclist, you rely on the crankset to turn the power generated by your legs into forward motion, making it one of the most important components of your ride.

The crankset consists of two or three chainrings attached to the pedal arms which rotate around the bottom bracket spindle. The chainrings determine the gear ratios, which affect how easy or difficult it is to pedal.

Different types of cranksets on the market include compact, standard, and triple. Compact cranksets have smaller chainrings, making it easier to climb hills. Standard cranksets have larger chainrings, allowing for faster speeds on flat terrain. Triple cranksets have three chainrings, providing a wider range of gear ratios for more versatility in different riding conditions.

Choosing the right crankset depends on your riding style and the terrain you will be riding on. As we move into understanding how the bicycle drivetrain works, it’s important to keep in mind how the crankset interacts with the rest of the components.

How the Bicycle Drivetrain Works

Pedaling a bicycle turns the chain, which then rotates the rear wheel and propels the bike forward. As simple as it may seem, the bicycle drivetrain is a complex system that involves several components working together in harmony. The bicycle drivetrain consists of the crankset, chain, cassette, derailleur, shifters and pedals. By manipulating the gear ratios, cyclists can adjust the resistance level and maintain a comfortable pedaling cadence.

To understand how the bicycle drivetrain works, let’s take a look at the table below. The table compares the gear ratios of a 2×10 drivetrain, where the front chainring has 2 gears and the rear cassette has 10 gears. By shifting gears, cyclists can achieve different combinations of gear ratios to suit different terrain conditions. For instance, using the small chainring with the larger cogs will result in an easier gear for uphill climbs. On the other hand, using the large chainring with the smaller cogs will result in a harder gear for flat or downhill sections. Thus, understanding pedal rotation and gear shifting techniques can help cyclists optimize their cycling performance.

Maintaining and upgrading your bicycle drivetrain is crucial to ensure a smooth and efficient ride. From cleaning and lubricating the chain to replacing worn-out components, proper maintenance can extend the lifespan of your drivetrain and prevent costly repairs. In the next section, we will discuss some tips and tricks on how to maintain and upgrade your bicycle drivetrain.

Maintaining and Upgrading Your Bicycle Drivetrain

To keep your drivetrain running smoothly, you should regularly clean and lubricate the chain. A dirty chain can reduce efficiency by up to 12%. Here are some tips for lubricating chains:

- Use a good quality chain lubricant and apply it sparingly. Too much lubricant can attract dirt and grime, which can cause more problems.

- Wipe off excess lubricant with a clean rag after applying it. This will prevent the excess lubricant from attracting dirt and grime.

- Apply lubricant to the chain after riding, not before. This will allow the lubricant to penetrate the chain while it is still warm and will help it to stick better.

Another important aspect of maintaining your drivetrain is ensuring that you have the proper gear ratio for your riding needs. If your gears are too high or too low, it can cause unnecessary wear and tear on your drivetrain. Here are some tips for proper gear ratio:

- Choose a gear that allows you to pedal comfortably at a cadence of 60-90 revolutions per minute (RPM). This will help you maintain a consistent speed and reduce stress on your knees.

- Use lower gears when climbing hills to reduce strain on your legs and lower back.

- Use higher gears when descending hills to prevent your legs from spinning too fast and causing unnecessary wear on your drivetrain.

Frequently Asked Questions

What is the history of the bicycle drivetrain?

The bicycle drivetrain has undergone extensive evolutionary changes to improve efficiency and performance. Its impact on modern bicycle design is undeniable, as it allows for smoother gear shifts and better power transfer. These advancements have revolutionized the cycling industry.

How do different types of terrain affect bicycle drivetrains?

Maintaining drivetrains is important for optimal performance on different terrains. Cleaning techniques such as regularly wiping down and degreasing can prevent buildup and corrosion. Proper lubrication can also prolong the life of drivetrain components.

Can you use a bicycle drivetrain on other types of vehicles?

I investigated the theory that bicycle drivetrains can be used on other vehicles. Custom bicycle builds and modifying existing vehicles can incorporate these drivetrains, but it requires technical knowledge and precision to ensure compatibility.

How does the weight of a rider affect the performance of a bicycle drivetrain?

The weight of the rider affects the performance of the bicycle drivetrain by altering the pedaling efficiency and gear ratios. Proper chain lubrication is crucial to maintain optimal function.

What are some common mistakes people make when maintaining their bicycle drivetrain?

Common mistakes in maintaining a bicycle drivetrain include neglecting chain maintenance and improper gear alignment. Neglecting regular chain cleaning and lubrication can cause wear and tear, while improper gear alignment can lead to poor shifting and increased wear on the drivetrain components.

Conclusion

Well folks, that concludes our discussion on the bicycle drivetrain. I hope by now you’ve got a clear understanding of the components and how they work together to propel your bike forward.

But let me tell you, this isn’t just an ordinary machine. It’s a marvel of engineering that can take you to places you never thought possible. The sheer power and efficiency of the bicycle drivetrain is something to behold. With just a few strokes of the pedals, you can cruise at high speeds and conquer even the steepest of hills.

And the best part? You have complete control over this machine. With proper maintenance and upgrades, you can fine-tune your bike to meet your exact needs and preferences.

So what are you waiting for? Get out there and experience the thrill of the bicycle drivetrain for yourself!