As an experienced bike rider, I understand how crucial it is to maintain my cherished bicycle properly. A key part of this maintenance involves making sure the wheel bearings are adequately lubricated, which aids in minimizing friction and wear on the components that move.

However, not all greases are created equal, and choosing the right type can make a significant difference in the longevity and performance of your bike. In this article, I will delve into the topic of what type of grease is best for bicycle wheel bearings.

I will cover the two main types of grease that are commonly used – lithium and synthetic – and explain the advantages and disadvantages of each. Additionally, I will provide guidance on what factors to consider when choosing the right grease and how to properly apply it to your bike’s wheel bearings.

By the end of this article, you will have a thorough understanding of the importance of grease for your bicycle’s wheel bearings and the knowledge to make an informed decision on what type of grease to use.

Key Takeaways

- Choosing the right grease can impact performance and longevity of bicycle wheel bearings.

- Lithium and synthetic grease are the two main types of grease used for bicycle wheel bearings.

- Synthetic grease offers superior resistance to water, extreme temperatures, and heavy loads compared to lithium grease.

- Proper application of high-quality, waterproof grease and regular maintenance of moving parts is crucial for optimal performance and longevity of bicycle wheel bearings.

The Importance of Lubricating Your Bicycle Wheel Bearings

Don’t neglect the importance of lubricating your bike’s wheel bearings – it can make all the difference in your ride! The frequency of lubrication depends on how often you ride and the conditions you ride in. If you ride frequently or in wet and dirty conditions, you’ll need to lubricate your bearings more often.

A good rule of thumb is to lubricate your bearings every three months or every 1,000 miles, whichever comes first.

Signs of inadequate lubrication include a rough or gritty feeling when spinning the wheel, excessive noise, and even damage to the bearing itself. If you notice any of these signs, it’s time to clean and re-grease your bearings.

Failure to do so can result in premature wear and damage to your wheel bearings. Understanding lithium grease and its properties is key to properly lubricating your bike’s wheel bearings.

Understanding Lithium Grease

I’ve used lithium grease extensively on my bicycle wheel bearings, and I think it’s important to understand its composition and properties.

Lithium grease is a thick, white lubricant that’s made by mixing lithium soap and mineral oil.

It’s a versatile lubricant that has both pros and cons, and it’s best suited for certain applications such as wheel bearings, ball joints, and chassis lubrication.

Composition and Properties

The composition of bicycle wheel bearing grease can greatly affect its properties, much like the ingredients in a recipe can impact the taste and texture of a dish. The right grease composition can provide better lubrication benefits, leading to smoother and longer-lasting operation of the wheel bearings.

Generally, bicycle wheel bearing grease is made up of a base oil, a thickening agent, and additives. The base oil can be mineral, synthetic, or a blend of both, while the thickening agent is usually a type of soap, such as lithium or calcium.

The properties of the grease, such as its viscosity and temperature range, depend on the type and amount of these components. Additives, such as rust inhibitors and anti-wear agents, can also be included to enhance the performance of the grease.

However, there are pros and cons to different grease compositions, as certain types may be better suited for certain conditions or applications.

Pros and Cons

You’ll want to weigh the advantages and disadvantages of different compositions when selecting the right lubricant for your bike’s moving parts. Here are some pros and cons of different types of grease:

- Lithium-based grease: commonly used and readily available, but can harden and become less effective in extreme temperatures.

- Synthetic grease: provides better performance in extreme temperatures, but may not be as widely available and can be more expensive.

- Ceramic grease: provides excellent resistance to water and corrosion, but is also more expensive and may not be compatible with certain materials.

- Biodegradable grease: environmentally friendly option, but may not provide the same level of protection as other types of grease and may not be compatible with all materials.

When selecting a grease, it’s important to consider its compatibility with the materials in your bike’s bearings, as well as its environmental impact. Understanding the pros and cons of different types of grease can help you make an informed decision about which one is best for your bike.

Moving on to the next section, let’s discuss the best applications for different types of grease.

Best Applications

Find the ideal lubricant for your bike’s various components by considering specific applications. Lithium-based grease is the most common type of grease used in bike wheel bearings due to its cost-effectiveness and ability to provide sufficient lubrication. However, it may not be the best option for extreme weather conditions or high-speed riding, as it tends to break down easily.

If you’re looking for a more high-performance option, synthetic grease may be the way to go. It offers superior resistance to water, extreme temperatures, and heavy loads, making it ideal for use in racing and off-road biking. Recommended brands include Finish Line, Park Tool, and Phil Wood, although there are alternative options available in the market.

With its superior lubricating properties, synthetic grease can help ensure optimal performance for your bike’s wheel bearings and other components.

Synthetic Grease: The High-Performance Option

Using synthetic grease for your bicycle wheel bearings is a great way to improve their performance and longevity. It offers superior resistance to water and extreme temperatures. Here are a few reasons why high-performance lubrication using synthetic grease is a better option than traditional grease:

-

Synthetic grease can withstand a wider range of temperatures without breaking down or becoming ineffective. This makes it ideal for use in a variety of weather conditions.

-

It is more resistant to water and other contaminants, which means it will last longer and require less maintenance than traditional grease.

-

Synthetic grease tends to be less prone to hardening or softening over time. This can help prolong the life of your bearings and reduce the likelihood of wear and tear.

-

It typically requires less frequent reapplication than traditional grease. This can save you time and effort over the long run.

Choosing the right grease for your bicycle wheel bearings can be a daunting task, but taking the time to consider the factors that are most important to you can help simplify the process. The next section will explore some of these factors in more detail, so you can make an informed decision about which type of grease is best for your needs.

Factors to Consider When Choosing the Right Grease

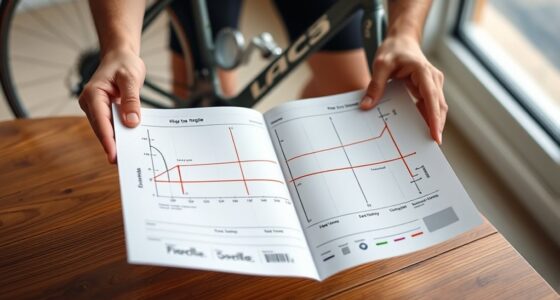

When deciding on the best lubrication for your bike, it’s important to take into account the specific conditions you’ll be riding in, in order to ensure optimal performance and avoid any potential mishaps. One of the key factors to consider is the viscosity level of the grease. Viscosity refers to the thickness or flow resistance of the grease, and it’s important to match it to the specific application. For bicycle wheel bearings, a medium to high viscosity grease is generally recommended, as it provides good protection against wear and tear, while still allowing for smooth rotation.

Another important factor to consider when choosing the right grease is the temperature range it can withstand. The grease must be able to withstand the heat generated by the friction between the wheel bearings and the axle, as well as fluctuations in temperature caused by changes in weather or riding conditions. A high-temperature grease is ideal for this application, as it can withstand temperatures up to 400 degrees Fahrenheit. It’s also important to choose a grease that is water-resistant, as this will help prevent rust and corrosion from developing in the wheel bearings. With these factors in mind, you can select a grease that will provide optimal protection and performance for your bicycle wheel bearings.

Transitioning into the subsequent section about how to apply grease to your bicycle wheel bearings, it’s important to note that proper application is key to ensuring optimal performance and longevity of your bike’s wheel bearings.

How to Apply Grease to Your Bicycle Wheel Bearings

When it comes to properly lubricating your bicycle wheel bearings, there are a few key steps that must be followed. First, ensure that the bearings are clean and free of debris before applying any grease.

Next, apply the grease evenly and thoroughly, making sure to cover all areas of the bearings. Finally, regular maintenance is crucial for optimal performance, so be sure to inspect and reapply grease as needed.

By following these steps and tips, you can ensure that your bicycle wheel bearings are properly lubricated and functioning at their best.

Steps for Proper Lubrication

First, make sure you’ve got the right type of grease for your bicycle wheel bearings. Not all greases are suitable for bicycle bearings, and using the wrong kind can damage your bike. Look for high-quality, waterproof grease specifically made for bicycle bearings.

Once you’ve got the right grease, it’s time to apply it to your wheel bearings. Start by removing the wheel from your bike and taking off the axle. Clean the bearings thoroughly with a degreaser and let them dry completely.

Then, apply a small amount of grease to each bearing, making sure to evenly distribute it. Be careful not to over-grease, as this can cause excess friction and slow down your ride. Finally, reassemble your wheel and axle and spin it to ensure the bearings are moving smoothly.

For optimal performance, it’s important to lubricate your bicycle wheel bearings regularly. The frequency of this maintenance task depends on how often you ride your bike and the conditions you ride in. As a general rule, it’s recommended to lubricate your wheel bearings every 1000 miles or every six months.

By following these steps, you can ensure that your bike’s wheel bearings are well-lubricated and ready to take on any ride.

Maintenance Tips for Optimal Performance

To keep your bike running smoothly, regularly maintaining its moving parts is key. When it comes to maintaining your bicycle wheel bearings, there are a few preventive measures you can take to ensure optimal performance.

First, always keep your bearings clean and free of debris. Dirt and grime can cause unnecessary friction and wear on the bearings, leading to premature failure. To clean your bearings, simply remove them from the wheel hub and wipe them down with a clean rag. Be sure to inspect them for any damage or signs of wear, such as pitting or rust.

Another common mistake when it comes to maintaining bicycle wheel bearings is over-greasing. While it may seem like more grease is better, too much grease can actually cause more harm than good. Over-greasing can lead to increased friction, which can cause the bearings to heat up and wear out faster.

To avoid over-greasing, apply a small amount of grease to the bearings and distribute it evenly. You can do this by rotating the wheel while applying the grease. Remember, a little grease goes a long way when it comes to maintaining your bicycle wheel bearings.

Frequently Asked Questions

How often should you lubricate your bicycle wheel bearings?

I have found that the optimal bicycle maintenance frequency for lubricating wheel bearings is every 1000-2000 miles. However, this can vary based on the effects of weather. Regular lubrication intervals will keep your wheels running smoothly and prevent damage.

Can you mix different types of grease for your bicycle wheel bearings?

Mixing greases for bicycle wheel bearings can cause compatibility issues. It’s important to use the same type of grease throughout the bearing system to prevent potential problems. As an experienced cyclist, I always stick to one type of grease to avoid any issues.

Is it necessary to clean your bicycle wheel bearings before applying grease?

As an experienced cyclist, I know the importance of regular maintenance for wheel bearings. Proper lubrication is crucial for optimal performance. Cleaning the bearings before applying grease ensures maximum effectiveness and longevity. Remember, "cleanliness is next to godliness."

Can you use WD-40 as a substitute for grease on your bicycle wheel bearings?

I do not recommend using WD-40 as a substitute for grease on bicycle wheel bearings. WD-40 is a solvent, not a lubricant, and will not provide sufficient protection. Instead, consider alternatives such as lithium or synthetic grease.

How do you know when it’s time to replace the wheel bearings on your bicycle?

Replacing wheel bearings is crucial to maintaining a smooth ride. Signs of wear include grinding or clicking sounds, wobbling, and reduced speed. Replacement options include ceramic or steel bearings. Preventative maintenance tips include regular cleaning and lubrication.

Conclusion

In conclusion, proper lubrication of your bicycle wheel bearings is crucial for the smooth operation and longevity of your bike. As an experienced cyclist, I recommend using a lithium or synthetic grease for optimal performance.

Lithium grease is a great all-purpose option, while synthetic grease offers high-performance and longer-lasting protection. When choosing the right grease for your bicycle wheel bearings, consider the weather conditions, type of riding you do, and the quality of your bearings.

Applying grease correctly is also important to ensure maximum benefits. Remember to clean the bearings thoroughly before applying grease, and apply just enough to cover the entire surface without over-packing.

As the famous cyclist Eddy Merckx once said, "Don’t buy upgrades, ride up grades."By properly lubricating your bicycle wheel bearings, you can ensure a smooth ride and avoid unnecessary wear and tear on your bike. So, the next time you hit the road or trail, make sure your bearings are well-greased and ready for the ride ahead.