To read wind-tunnel data like a pro, start by understanding your test’s objectives and setup, focusing on key measurements like lift and drag coefficients. Review pressure distribution and surface measurements to identify flow separation and turbulence regions. Use flow visualization to see airflow patterns, then analyze how modifications impact performance. By interpreting this data accurately, you’ll open valuable insights to optimize designs—keep exploring, and you’ll master these techniques effortlessly.

Key Takeaways

- Understand the specific test objectives and focus on relevant data such as lift (Cl), drag (Cd), and pressure distribution curves.

- Analyze flow visualization alongside surface measurements to identify flow patterns, vortices, and separation points.

- Pay attention to flow separation zones and turbulence indicators to assess boundary layer behavior and flow stability.

- Use pressure distribution data to verify flow attachment and detect high or low pressure zones critical for performance.

- Compare experimental data with design goals to identify areas for aerodynamic improvements and effective flow control strategies.

Understanding Wind-Tunnel Testing Objectives and Setup

Understanding wind-tunnel testing objectives and setup is essential for obtaining accurate and meaningful data. When working with scale modeling, your goal is to replicate real-world conditions as closely as possible, ensuring the model’s size and shape accurately represent the actual object. Proper setup involves configuring the test section, ensuring steady airflow, and selecting appropriate flow visualization techniques. These techniques help you observe airflow patterns, identify turbulence, and understand how design changes influence aerodynamics. Clear objectives guide your testing process, whether you’re evaluating lift, drag, or stability. Additionally, understanding the contrast ratio of your testing environment can significantly impact the visibility of flow features and overall data quality. Proper calibration of equipment and understanding tuning parameters can further enhance data accuracy and repeatability. Considering the role of automation in data collection can also streamline the testing process and reduce human error. By carefully planning your setup and focusing on flow visualization, you improve data quality, making it easier to interpret results and apply findings effectively.

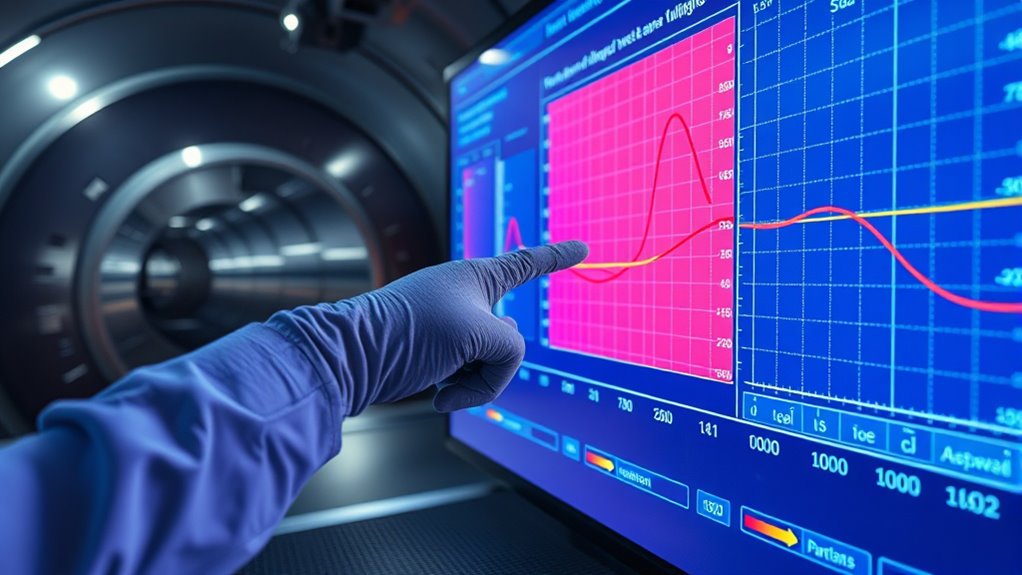

Interpreting Aerodynamic Coefficients and Data Plots

Interpreting aerodynamic coefficients and data plots is essential for evaluating how a design performs under different flow conditions. These plots reveal flow separation points and turbulence modeling effects, which impact lift and drag. To analyze effectively:

Understanding aerodynamic data helps identify flow separation and turbulence effects impacting lift and drag.

- Examine lift coefficient (Cl) trends to identify stall or flow separation onset.

- Assess drag coefficient (Cd) variations for turbulence effects and flow stability.

- Review pressure distribution curves to infer flow attachment or separation regions.

- Recognize how automation in business can influence data collection and analysis methods, enabling more accurate interpretation of aerodynamic performance. Incorporating data visualization techniques can further enhance insight into complex flow behaviors.

- Understand the asset division principles that guide the fair allocation of resources during data analysis processes, ensuring objective evaluations.

- Staying aware of AI security vulnerabilities is important when utilizing automated tools for data interpretation, as it can affect the integrity and accuracy of results.

Understanding these aspects helps you recognize flow separation issues and turbulence influences that affect performance. Clear interpretation of coefficients and plots allows for targeted modifications, optimizing aerodynamic efficiency and safety. Mastering this skill is vital for translating raw data into meaningful insights about your model’s aerodynamic behavior.

Analyzing Pressure Distribution and Surface Measurements

Examining pressure distribution and surface measurements provides direct insight into how airflow interacts with your model’s surface. By analyzing pressure data, you can identify areas of high or low pressure, revealing flow separation or attachment points. Surface measurements, such as surface pressure sensors, help validate flow visualization results and guarantee data accuracy. Use the table below to compare key measurement aspects: measurement accuracy is essential for ensuring reliable and precise data collection. Additionally, understanding aerodynamic principles can enhance your interpretation of the data, leading to more effective design modifications.

| Measurement Type | Purpose |

|---|---|

| Pressure Distribution | Visualize pressure variation across surface |

| Surface Measurements | Validate flow visualization and detect anomalies |

This approach helps you interpret flow behavior precisely, facilitating accurate data validation and a deeper understanding of aerodynamic performance. Additionally, understanding the role of sleep and mental health can enhance your focus and decision-making during analysis. Incorporating knowledge of AI in entertainment technology, such as advanced hardware like Snapdragon 8 Gen 3, can also inspire innovative approaches to data processing and visualization techniques.

Recognizing Common Measurement Techniques and Their Implications

Recognizing the most common measurement techniques in wind-tunnel testing is essential for obtaining reliable and meaningful data. These methods help you interpret flow behavior and turbulence accurately.

- Flow Visualization: Techniques like smoke or dye injection reveal flow patterns, helping you identify separation points and vortices. They provide immediate visual insights into airflow behavior. Additionally, advancements in visualization methods can improve the resolution and clarity of flow features, aiding in more precise analysis. Modern visualization tools can also help detect subtle flow phenomena that traditional techniques might miss.

- Pressure and Surface Measurements: Sensors record pressure distribution, revealing aerodynamic forces and potential areas of flow disturbance. Calibration of these sensors is crucial to ensure data accuracy and reliability. Proper calibration procedures are vital to minimize measurement errors and enhance data fidelity.

- Turbulence Measurement: Hot-wire anemometry and laser Doppler velocimetry quantify turbulence intensity and scales, offering detailed insight into flow stability and energy dissipation. These techniques often require complex data interpretation to differentiate between turbulence levels and measurement noise. Understanding the turbulence characteristics helps in assessing flow conditions more thoroughly.

- Data Accuracy and Limitations: Understanding the measurement techniques’ limitations ensures you correctly interpret wind-tunnel data, avoiding misjudgments caused by measurement limitations. Being aware of the instrument resolution and environmental factors can significantly impact the validity of the results. Recognizing these factors allows for better experimental design and data analysis.

Applying Wind-Tunnel Data to Improve Design Performance

By leveraging wind-tunnel data effectively, you can make targeted design improvements that enhance aerodynamic performance. Focus on analyzing flow separation points, which indicate where the boundary layer detaches from the surface. Understanding boundary layer behavior helps you identify areas prone to drag increase or instability. If flow separation occurs prematurely, consider redesigning surfaces to smooth airflow or delay separation, reducing drag and improving efficiency. Adjusting the shape or surface texture can also stabilize the boundary layer, maintaining attached flow longer. Recognizing the significance of boundary layer control techniques allows for more precise modifications to improve airflow. Implementing these insights enables you to fine-tune your design, minimize turbulence, and optimize lift-to-drag ratios. Additionally, incorporating aerodynamic surface features can help maintain flow attachment in critical regions. Being aware of bank and finance concepts such as resource allocation and risk management can also inform strategic decisions during the design process. Incorporating performance metrics derived from wind-tunnel tests can guide iterative improvements and validation steps. Ultimately, applying wind-tunnel data in this way enables you to create aerodynamic surfaces that perform better under real-world conditions.

Conclusion

Now that you’ve got the hang of reading wind-tunnel data like a pro, remember it’s a essential tool for refining your designs—just like the engineers of the Wright brothers’ era. With a keen eye for coefficients, pressure maps, and measurement techniques, you can uncover insights that boost performance and aerodynamics. So, keep experimenting, stay curious, and don’t let your curiosity lag behind—like a good pilot, always stay ahead of the wind.