Just as a maestro readies themselves for a magnificent concert, pumping up a bike tire demands accuracy and skill. Through this detailed guide, I’m going to lead you through the detailed process of inflating a bike tire, guaranteeing peak performance and security.

From gathering the necessary tools to identifying the valve type, each detail will be meticulously explained.

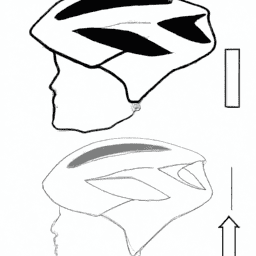

So, grab your pump, tighten your helmet, and let’s embark on this journey to achieve perfectly inflated bicycle tires.

Key Takeaways

- Choose a suitable pump for your tire valve type (Schrader or Presta).

- Maintain proper tire pressure using a pressure gauge.

- Regularly clean and lubricate the pump for smooth operation.

- Check the tire pressure frequently and avoid overinflation for optimal performance and safety.

Gather the necessary tools

You’ll need to gather all the necessary tools to blow up your bicycle tire. First, make sure you have a pump that is suitable for your tire valve. There are two common types: Schrader and Presta. Choosing the right pump is crucial for a successful inflation. If you’re unsure, consult your bicycle’s manual or ask a professional at a bike shop.

Additionally, it’s important to troubleshoot common tire inflation issues before starting. Check for any leaks or punctures in the tire and make sure the valve is properly secured.

Now that you have your pump and have addressed any potential issues, you’re ready to move on to the next step: checking the tire pressure.

Check the tire pressure

Before checking the tire pressure, make sure you have a pressure gauge. It is essential to maintain proper tire pressure for optimal performance and safety. The importance of maintaining proper tire pressure cannot be overstated.

Insufficient tire pressure can lead to decreased stability, reduced traction, and increased stopping distance. On the other hand, excessive tire pressure can cause a harsh, uncomfortable ride and uneven tire wear.

When checking the tire pressure, there are a few common mistakes to avoid. Firstly, ensure that the tires are cool before measuring the pressure. Heat generated during driving can increase tire pressure, giving inaccurate readings. Secondly, use a reliable pressure gauge to get an accurate measurement. Inaccurate readings can lead to incorrect tire pressure adjustments.

Now that the tire pressure is checked, it’s time to find a suitable pump to inflate the tire.

Find a suitable pump

Now that you’ve checked the tire pressure, it’s time to find a pump that’s suitable. Choosing the right pump is crucial for efficiently inflating your bicycle tire. Here are some factors to consider:

- Compatibility: Ensure that the pump is compatible with your valve type, whether it’s a Presta or Schrader valve.

- Pressure Gauge: Look for a pump with a built-in pressure gauge, allowing you to monitor the tire pressure accurately.

- Durability: Opt for a pump made from high-quality materials that can withstand frequent use.

- Portability: If you often ride long distances, a compact and lightweight pump will be more convenient to carry.

Maintaining the pump is equally important. Regularly clean and lubricate the pump’s moving parts to ensure smooth operation and extend its lifespan. Additionally, store the pump in a dry place to prevent rusting.

With a suitable pump in hand, the next step is to identify the valve type for proper inflation.

Identify the valve type

To properly inflate your bicycle tire, it’s important to identify the valve type. There are two main types of valves commonly found on bicycle tires: Schrader and Presta.

The Schrader valve is the more common type, usually found on mountain bikes and most standard bicycles. It has a larger diameter and is similar to the valves found on car tires.

On the other hand, the Presta valve is typically found on road bikes and high-performance bicycles. It is narrower and requires a specific pump head for inflation.

Proper identification of the valve type is crucial to ensure compatibility with your pump and prevent any damage to the valve or tire. Additionally, regular valve maintenance, such as checking for leaks or debris, is essential for optimal performance.

Now, let’s move on to the next step: removing the valve cap.

Remove the valve cap

First, unscrew the valve cap from your tire. Proper valve maintenance is essential for the longevity and performance of your bicycle tire. The valve cap serves as a protective cover, preventing dirt and debris from entering the valve and causing damage. It also helps to maintain the air pressure in the tire by providing a tight seal.

There are different types of valve caps available, including plastic caps and metal caps. Plastic caps are lightweight and often come in various colors, while metal caps are more durable and provide a stylish touch.

Once you have removed the valve cap, you can proceed to attach the pump to the valve, ensuring a secure connection for efficient inflation.

Attach the pump to the valve

After removing the valve cap, you can simply attach the pump to the valve for inflation. To ensure a secure and efficient connection, follow these pump attachment techniques:

- Align the pump nozzle with the valve stem to ensure a proper fit.

- Push the nozzle firmly onto the valve to create an airtight seal.

- Lock the pump onto the valve by flipping the lever or tightening the connector.

- Check for any leaks by listening for hissing sounds or feeling for air escaping.

If you encounter any issues with the valve connection, troubleshoot by:

- Checking for debris or dirt that may obstruct the valve.

- Adjusting the pump nozzle position for a better fit.

- Inspecting the valve for any damages or obstructions.

Remember, a proper pump attachment is crucial for inflating the tire effectively.

Now, let’s move on to the next step and pump air into the tire.

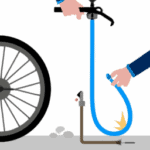

Pump air into the tire

Now, you can start pumping air into your tire. Before you begin, it’s important to check the condition of your tire. Inspect it for any punctures, cuts, or bulges that could cause a blowout. If everything looks good, proceed with caution.

Attach the pump securely to the valve, ensuring a tight seal. Begin pumping air into the tire by using smooth, controlled motions. Be mindful of the pressure gauge on the pump, as you want to reach the recommended PSI for your specific tire. If you encounter any issues, such as air escaping or the pump not fitting properly, double-check the connection and try again.

Once you’ve successfully inflated the tire, it’s time to monitor the pressure gauge to ensure you’ve reached the desired level. With the tire fully inflated, you’re ready to move on to the next step.

Monitor the pressure gauge

After pumping air into the bicycle tire, it is crucial to monitor the pressure gauge to ensure that the tire is inflated to the proper level. Maintaining proper tire pressure is of utmost importance for optimal performance and safety.

Riding with underinflated tires can lead to increased rolling resistance, decreased handling capabilities, and a higher risk of flats. On the other hand, overinflated tires can result in a harsh ride, reduced traction, and a higher susceptibility to punctures. Therefore, it is essential to use a pressure gauge to accurately measure the tire pressure.

However, there are common mistakes to avoid when using a pressure gauge. These include not attaching the gauge properly, not waiting for the reading to stabilize, and not checking the pressure when the tire is cool. By avoiding these mistakes, you can ensure accurate readings and make informed decisions about the tire pressure.

Moving on to the next step, let’s discuss how to inflate the tire to the recommended pressure.

Inflate the tire to the recommended pressure

To achieve optimal performance and safety, it’s important to inflate the tire to the recommended pressure. Monitoring the pressure gauge throughout the process is crucial to prevent overinflation. Overinflating the tire can lead to a harsh ride and increased risk of a blowout.

When inflating the tire, start by attaching the pump securely to the valve. Ensure a tight seal to prevent any air from escaping. Then, using the pump, begin adding air to the tire. Keep a close eye on the pressure gauge to ensure you reach the recommended pressure. It’s important to inflate the tire gradually, checking the gauge frequently to avoid overinflation.

Once the tire is at the recommended pressure, it’s time to detach the pump from the valve, preparing for the next step of the process.

Detach the pump from the valve

You can detach the pump from the valve once the tire is at the recommended pressure.

To properly detach the pump from the valve, first, make sure that the tire is fully inflated. Release any remaining air pressure by pressing the small metal or plastic valve stem on the side of the valve.

Once the pressure is released, grip the pump firmly near the valve and twist it counterclockwise to loosen it from the valve. Gently pull the pump away from the valve, being careful not to damage the valve or the tube. It is important to detach the pump slowly and steadily to avoid any sudden release of pressure.

Now that the pump is detached, you can proceed to replace the valve cap, ensuring it is securely in place.

Replace the valve cap

Now that the pump is detached, it’s time to securely replace the valve cap. Valve maintenance is essential for keeping your bicycle tire in optimal condition. The valve cap plays a crucial role in protecting the valve from dirt, dust, and moisture, ensuring its longevity. There are different types of valve caps available, each with its own pros and cons. Let’s take a closer look at three common options:

| Valve Cap Type | Pros | Cons |

|---|---|---|

| Plastic Cap | Lightweight and inexpensive | Prone to cracking and breaking |

| Metal Cap | Durable and long-lasting | Can be heavy and more expensive |

| Dust Cap with O-ring | Excellent seal against contaminants | May be harder to remove and replace |

By selecting the right valve cap for your needs, you can enhance the lifespan of your tire valve. Now, let’s move on to the next step and check for any leaks or damage.

Check for any leaks or damage

First, make sure to carefully inspect the valve and surrounding areas for any signs of leaks or damage. This step is crucial to ensure the proper functioning of the bicycle tire.

To effectively check for punctures, use a solution of soapy water and apply it to the valve and tire surface. Look for any bubbles forming, as this indicates a leak. If any leaks are detected, it is important to repair them promptly to prevent further damage.

Additionally, examine the tire for any visible damage, such as cuts or tears, which may compromise its integrity. Taking the time to thoroughly inspect the valve and tire will help identify and address any issues before proceeding to the next step. This will ensure optimal performance and safety when inflating the tire.

Moving on, we will now test the tire’s firmness to confirm its readiness for use.

Test the tire’s firmness

To ensure the tire is ready for use, check its firmness. This step is crucial in maintaining optimal tire pressure and ensuring a smooth ride. Start by gently pressing the tire with your thumb or palm to assess its firmness. If the tire feels too soft or spongy, it may indicate a puncture or insufficient air pressure. To visually inspect the tire, look for any bulges or deformities, as these can also impact its firmness. As a visual aid, refer to the table below for a quick reference on what to look for:

| Tire Firmness | Description |

|---|---|

| Firm | Feels solid and rigid, with minimal give when pressed |

| Spongy | Feels soft and pliable, with noticeable give when pressed |

Once you have assessed the firmness and condition of one tire, repeat the process for the other tire to ensure both are in optimal condition.

Repeat the process for the other tire

Start by assessing the firmness and condition of the second tire to ensure it is also in optimal condition. To properly inflate your bicycle tires, it is crucial to avoid common mistakes that can lead to tire damage or inefficient air pressure.

Here are four important tips for maintaining optimal tire pressure:

-

Use a pressure gauge: Always check the tire pressure using a reliable pressure gauge to avoid under or over-inflating the tire.

-

Inflate to the recommended PSI: Refer to the manufacturer’s guidelines for the recommended PSI (pounds per square inch) specific to your bicycle tires.

-

Avoid using your mouth: Using your mouth to blow air into the tire can introduce moisture and contaminants, leading to premature wear and tear.

-

Regularly check for leaks: Inspect the tire for any visible punctures or leaks before inflating.

By following these tips, you can avoid common mistakes when inflating bicycle tires and ensure your tires are in optimal condition.

Now, let’s move on to the next section and enjoy your fully inflated bicycle tires!

Enjoy your fully inflated bicycle tires!

After successfully inflating one tire, it’s time to repeat the process for the other tire. This ensures that both tires are evenly inflated, providing a balanced and smooth ride.

To do this, simply attach the pump to the valve of the second tire, ensuring a secure connection. Begin pumping, using even and steady strokes to gradually increase the pressure.

It’s essential to get a pump that is compatible with your bicycle’s valve type to ensure a proper fit and efficient inflation.

Proper tire inflation is crucial for optimal bike performance and safety. It improves traction, reduces rolling resistance, and prevents flats.

Overinflated tires can lead to a harsh ride and increased risk of punctures, while underinflated tires can cause sluggish handling and increased rolling resistance.

So, take the time to inflate your bicycle tires correctly, and enjoy the benefits of a smooth and efficient ride.

Frequently Asked Questions

How do I gather the necessary tools to blow up a bicycle tire?

I gather the necessary tools to blow up a bicycle tire by assembling a tire pump, tire gauge, and a patch kit. These tools are essential for inflating the tire to the correct pressure and fixing any punctures.

What is the recommended tire pressure for a bicycle?

The recommended tire pressure for a bicycle is typically indicated on the sidewall of the tire. Proper tire pressure is crucial for optimal performance, handling, and safety. Regular tire maintenance, including checking and adjusting pressure, is essential for a smooth and efficient ride.

How do I identify the valve type on my bicycle tire?

To identify the valve type on your bicycle tire, look for either a Schrader valve or a Presta valve. To properly use each valve, make sure to have the correct pump and adapter. Avoid common mistakes, like overinflating or using the wrong valve type.

What should I do if I notice any leaks or damage while inflating the tire?

If I notice any leaks or damage while inflating the tire, I’ll immediately stop and inspect for the source. Repairing leaks can be done using patch kits or sealants. Preventing damage is important to ensure the tire’s longevity and safety.

Can I use a different type of pump if I don’t have a suitable one for my bicycle tire?

If you don’t have a suitable pump for your bicycle tire, there are alternative pump options available. However, it’s important to note that using a different pump may pose potential risks such as over or under-inflation, damaging the tire or valve.

Conclusion

In conclusion, properly inflating your bicycle tires is crucial for a smooth and efficient ride. By following the steps outlined in this article, you can ensure that your tires are fully inflated and ready to go.

Did you know that a study conducted by the National Highway Traffic Safety Administration found that underinflated tires are a contributing factor in over 660 fatalities each year? Taking the time to inflate your bicycle tires correctly can not only improve your riding experience but also enhance your safety on the road.

So, grab your tools and get ready to enjoy a smooth and comfortable ride!