As someone who is passionate about cycling, I recognize the significance of maintaining my bicycle in excellent shape. The chain of the bicycle is among its most vital components, which may suffer wear or damage as time passes. Therefore, it is important to be knowledgeable about preserving and fixing your bike’s chain, which involves identifying and extracting the master link when it needs to be repaired or replaced.

Before we get started, let’s make sure we’re on the same page about the basics of a bike chain. A bike chain is a series of interconnected metal links that transfer power from the pedals to the wheels. Each link has two pins that fit into the chainring and cassette teeth, and when you pedal, the chain rotates, causing the wheels to turn.

The master link is a special link that’s used to connect and disconnect the chain easily, making it an essential component for bike maintenance and repair.

Key Takeaways

- The master link is a special link used to connect and disconnect the chain easily, making it an essential component for bike maintenance and repair.

- There are several methods to find the master link on a bicycle chain, including checking for visible indicators, using a magnet, and using a chain tool.

- Visible indicators include an outer plate that is slightly different in shape or color from the rest of the plates or a distinct marking on the chain.

- The master link can be removed by locating it on the chain and using pliers to remove the clip holding it together.

Understand the Basics of a Bike Chain

If you want to find the master link on your bike chain, you first need to understand the basics of how it works.

The chain is an essential component of a bicycle that transfers power from the pedals to the rear wheel. It’s made up of a series of links that interlock with each other to form a continuous loop.

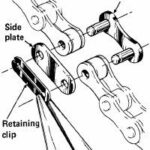

Each link consists of two outer plates and two inner plates, which are joined together by a pin. The pins are held in place by bushings that allow them to rotate freely. It’s important to note that bike chains wear over time and need to be replaced periodically.

Chain wear indicators are used to determine when the chain has stretched beyond its usable limit. These indicators are usually found on the inner plates and can be seen between the links.

Now that we know the basic chain anatomy and how to identify chain wear indicators, let’s move on to the next step of finding the master link.

Look for the Master Link

When looking for the master link on a bicycle chain, there are several methods that can be used.

Firstly, I always check for visible indicators, such as a different color or shape on one of the links.

If that doesn’t work, I use a magnet to try and locate the link with a different composition of metal.

Finally, if all else fails, I use a chain tool to carefully remove links until I find the master link.

Check for Visible Indicators

Take a close look at the chain and you might spot some visible indicators that will help you find the master link. One such indicator is the presence of an outer plate that is slightly different in shape or color from the rest of the plates. Another indicator is a distinct marking on the chain, such as a brand logo or a unique pattern. These visible indicators are usually found on one side of the chain, so make sure to inspect both sides carefully.

To further aid in your search for the master link, you can also consult a wear chart to determine the likelihood of its location. A wear chart is a table that compares the amount of wear on different parts of the chain over time. By checking the wear pattern on your chain, you can narrow down the possible location of the master link. Here is an example of a wear chart:

| Chain length | Wear percentage | Possible master link location |

|---|---|---|

| 12 inches | 0% – 0.5% | Anywhere along the chain |

| 12 inches | 0.5% – 1% | 1 inch from either end |

| 12 inches | 1% – 2% | 2 inches from either end |

| 12 inches | 2% – 3% | 3 inches from either end |

Using a magnet is another effective method for finding the master link. Simply run a magnet along the chain and it will stick to the master link, which is usually made of steel. However, be sure to remove any dirt or debris from the chain beforehand to ensure accuracy.

Use a Magnet

You can easily locate the elusive piece that connects your bike’s chain by using a simple tool – a magnet. But not just any magnet won’t do the job. You need a strong magnet, such as a rare earth magnet, to attract the metal master link.

To find the master link, simply run the magnet along the chain until it sticks to the master link. Then, carefully pull the chain apart at the master link to remove it.

If you don’t have a strong magnet, there are alternative methods that you can try. You can use a flashlight to shine light on the chain and look for the master link, or you can feel for the link by running your fingers along the chain. However, these methods may not be as effective as using a magnet.

Now that you’ve located the master link, you can proceed with removing or repairing the chain using a chain tool.

Use a Chain Tool

Now that you’ve located the elusive connector, it’s time to use the chain tool, which is like a surgeon’s scalpel for your bike’s chain. Chain maintenance is an essential aspect of bike ownership, and knowing how to repair a broken chain can save you from a lengthy walk home.

Here’s how to use a chain tool to fix a broken chain:

- First, align the chain tool with the chain pin that needs to be removed.

- Tighten the chain tool’s handle until the pin is pushed out of the link.

- Repeat the process on the other side of the link.

- To reattach the chain, line up the two ends and insert the pin back into the link.

Using a chain tool is a relatively straightforward process, but it’s crucial to be precise when removing and reinserting the chain pin. Once you’ve successfully removed the master link, it’s time to move on to the next step and remove the link entirely.

Remove the Master Link

First, locate the master link on your bike chain by looking for the link that has a clip holding it together. Not all chains have a master link, so it is important to check for master link compatibility before attempting to remove it. Some chains may require alternative removal methods, such as using a chain tool to push out a pin.

Once you have located the master link, use a pair of pliers to remove the clip holding the link together. Be sure to keep the clip in a safe place so it does not get lost. Then, gently pull the chain apart at the master link. The link should come apart easily, but if it is difficult to separate, you may need to use a pair of pliers to pry it apart. With the master link removed, you can now proceed to replace it with a new one.

Replace the Master Link

Let’s get to work replacing the clip on the chain so we can get back to riding!

The first step in replacing a master link is to ensure that the new link is compatible with your chain. Master links come in different sizes and shapes, so it’s important to match the new link to the old one. If you’re unsure about the compatibility of your chain and master link, consult your bike manual or a local bike shop for assistance.

Once you have the correct master link, you can start replacing the old one. First, remove any alternative chain connectors that may be in place. Then, line up the new master link with the chain and snap it into place. Make sure that the clip is properly seated and engaged, and that the chain is running smoothly over the gears.

With the new master link in place, you can now test your chain to ensure that it’s working properly.

Test Your Chain

Before hitting the road, it’s important to ensure that your bicycle chain is in good working condition. To do this, I always check for proper functionality by shifting gears and pedaling to see if the chain moves smoothly.

Additionally, I perform routine maintenance such as cleaning and lubricating the chain regularly to prevent wear and tear. By taking these simple steps, I can ensure that my chain remains in optimal condition for a safe and smooth ride.

Check for Proper Functionality

To ensure your bike chain is functioning properly, you should regularly check for any signs of wear or damage, such as rust or stiff links, as this could indicate the need for a new chain or repair. Checking for proper functionality is also important. You can do this by shifting through all the gears while pedaling, ensuring that the chain moves smoothly and quietly over the cassette and chainrings, and that there is no skipping or jumping.

To help you better understand how to check for proper functionality, here is a table outlining some common issues and their potential causes:

| Issue | Potential Cause | Solution |

|---|---|---|

| Chain skipping or jumping | Worn cassette or chainrings | Replace worn parts |

| Chain slipping off chainrings | Loose chain or worn chainring teeth | Tighten chain or replace worn parts |

| Chain making noise | Lack of lubrication or dirt buildup | Clean and lubricate chain |

Performing routine maintenance is the best way to prevent these issues from occurring in the first place. By keeping your bike chain clean and well-lubricated, you can ensure that it functions properly and lasts longer.

Perform Routine Maintenance

Regularly maintaining your bike’s chain is like giving it a refreshing spa treatment, ensuring its longevity and smooth functioning. One of the most important aspects of routine maintenance is chain lubrication. This process involves applying lubricant to the chain to reduce friction, protect against corrosion, and ensure smooth shifting.

The benefits of regular maintenance are numerous. By keeping your chain lubricated and clean, you can prevent premature wear and tear, reduce the risk of chain breakage, and improve your bike’s overall performance. Additionally, a well-maintained chain will reduce the amount of noise your bike makes while riding and make shifting easier.

So, make sure to take the time to properly maintain your chain and reap the benefits of a smoother, more efficient ride.

Frequently Asked Questions

How often should I check and replace my bicycle chain?

As a cyclist, I understand the importance of chain maintenance. Regularly checking and replacing your bicycle chain is crucial to ensure optimal performance and prevent damage to other components. Signs of a worn-out chain include skipping gears and chain elongation.

Can I use any type of master link on my bicycle chain?

When it comes to Master link compatibility, not all are created equal. Selecting the right master link is crucial for your bike chain’s performance. Make sure to choose one that matches the size and type of your chain.

Is it safe to ride my bike with a broken or missing master link?

Riding a bike with a broken or missing master link is not safe and can cause the chain to come apart. Repair options include replacing the link or the entire chain. Safety concerns should always be a top priority.

What tools do I need to remove and replace a master link?

I need a chain tool, pliers, and a quick link to remove and replace a broken master link. Bicycle chain maintenance requires careful attention to detail, as a faulty link can cause serious accidents. Always carry repair tools.

How do I know if my bike chain is too worn out to just replace the master link?

Assessing wear on a bike chain is crucial. A chain should be replaced if it has elongated by 1% of its original length. Measure the chain length to determine if it’s time for a replacement.

Conclusion

In conclusion, finding and replacing a master link on your bicycle chain may seem daunting, but it can be done with a little knowledge and patience. You can identify and locate the master link by understanding the basics of a bike chain. Removing and replacing the link requires the right tools and careful attention to detail.

Remember to test your chain after replacing the master link to ensure it’s properly functioning. As the saying goes, "a chain is only as strong as its weakest link."So, taking the time to maintain and replace the master link can make a significant difference in the longevity and performance of your bike.

So, get out there, inspect your chain, and don’t be afraid to tackle this task yourself. Your bike will thank you.