To maintain your gravel bike, you should regularly clean it after rides, focusing on removing dirt from the frame, drivetrain, and components using gentle rinsing and bike-specific cleaners. Keep your chain lubricated and inspect parts for wear or damage, replacing pads or components as needed. Protect your bike with rust prevention sprays and apply protective coatings to keep dirt at bay. Continuing to care for your bike ensures smooth performance and longer lifespan—there’s more to discover to keep it in top shape.

Key Takeaways

- Regularly clean your bike after muddy or gravel rides using gentle rinsing, bike-specific cleaners, and soft brushes to prevent dirt buildup.

- Lubricate the chain and drivetrain components regularly to ensure smooth shifting and prevent rust, especially after cleaning or riding in wet conditions.

- Inspect and maintain brakes, including pads, hoses, and fluid levels, replacing worn parts and bleeding hydraulic brakes annually.

- Protect metal and unpainted parts with rust-preventive coatings like CyclOn Vaseline and spray to prolong bike lifespan.

- Conduct periodic inspections, reapply protective coatings, and perform basic maintenance to keep your gravel bike in optimal condition.

The Essential Cleaning Routine for Gravel Bikes

Regular cleaning is key to keeping your gravel bike in top shape, especially after muddy or gravel-racing rides. After tough rides, focus on thoroughly cleaning your bike, paying close attention to the chain. Use a bike-specific cleaner on the drivetrain to remove dirt and grime, then scrub the chain with a brush to loosen debris. Rinse with low-pressure water to avoid damaging delicate components. A clean chain ensures smoother shifting and better lube absorption. Once the bike is dry, apply lube to the chain to prevent rust and reduce wear. For frame and other parts, specialized cleaning products help maintain appearance and performance. Incorporating proper maintenance techniques ensures your bike stays in optimal condition over time. Regularly inspecting your components and understanding how cleaning tools can improve your routine will keep your bike running smoothly and extend its lifespan. Additionally, using appropriate cleaning products tailored to bike materials can help prevent damage and preserve the bike’s finish. Moreover, understanding bike material care helps you choose the best products to protect your bike from environmental damage.

Tools and Supplies Needed for Effective Cleaning

To clean your gravel bike effectively, having the right tools and supplies on hand is essential. Start with a bike cleaner and environmentally-friendly cleaning products to protect your bike and the environment. Use brushes, including small brushes or old toothbrushes, to reach tight spots like derailleur pulleys and brake calipers. Microfiber cloths are perfect for wiping down surfaces without scratching. A garden hose or power washer helps rinse off dirt, while a bucket of warm soapy water and sponges aid in detailed cleaning. Incorporating proper maintenance techniques into your routine can help extend the lifespan of your bike components and ensure optimal performance. Using contrast ratio in your cleaning routine can also help you better assess the cleanliness and visibility of your bike’s components. Regularly inspecting your bike’s suspension system during cleaning can prevent issues and improve ride quality. Checking your braking system periodically ensures safety and effective stopping power. Optional equipment like a bike stand offers stability and easier access during cleaning. Incorporating data privacy considerations into your maintenance routine can help ensure your personal information stays secure during online purchases of cleaning supplies.

Step-by-Step Guide to a Spotless Gravel Bike

To get your gravel bike spotless, start by preparing it for cleaning—remove accessories, place it on a stand, and take off the wheels if needed. Next, rinse the frame and wheels gently, then scrub away dirt with bike-specific cleaner and a brush, paying special attention to the drivetrain. Regular cleaning is essential for keeping your bike in top condition and preventing the buildup of dirt that can hinder performance. Proper maintenance routines are essential for keeping your bike in top condition. To enhance your cleaning process and protect delicate components, consider using an appropriate eye protection that shields you from splashes and debris during cleaning. Finish by rinsing thoroughly, inspecting and lubricating the chain, and drying all parts to keep your bike in top shape. Using high-quality cleaning tools and solutions ensures a thorough maintenance routine that preserves your bike’s performance.

Prepare Your Bike

Before giving your gravel bike a thorough cleaning, it’s best to remove all accessories like bottles, bags, and lights. This makes it easier to clean your gravel bike effectively and helps keep all parts accessible. Start by placing your bike on a stable stand or surface. Gently rinse the frame and wheels with water to loosen dirt, mud, and dust. Use a bike-specific cleaner or mild soap, along with brushes and sponges, to scrub the frame, drivetrain, and hard-to-reach areas from top to bottom. Regular maintenance is key, so pay special attention to the drivetrain and components. After cleaning, rinse thoroughly to remove soap residues and dirt. Finish by drying the bike with a soft cloth or microfiber towel, helping keep your gravel bike in top shape for every ride. Proper storage and rust prevention also contribute to the longevity of your bike. Incorporating routine inspections and preventive maintenance can further extend the life of your bike and ensure optimal performance. Performing regular lubrication of moving parts is also essential for smooth operation and durability. Additionally, using proper cleaning techniques helps prevent damage to delicate components and preserves your bike’s appearance. Incorporating water park safety tips into your cleaning routine can also help prevent accidental damage or safety hazards during maintenance.

Clean Thoroughly and Rinse

Start by rinsing your gravel bike with a gentle stream of water to remove loose dirt and dust. This initial rinse prevents scratches and helps the cleaner work effectively. Next, apply a bike-specific cleaner or mild soap from top to bottom, ensuring dirt doesn’t settle into cleaned areas. Focus on these key steps:

- Rinse thoroughly to wash away soap and grime, avoiding high-pressure water that can damage bearings.

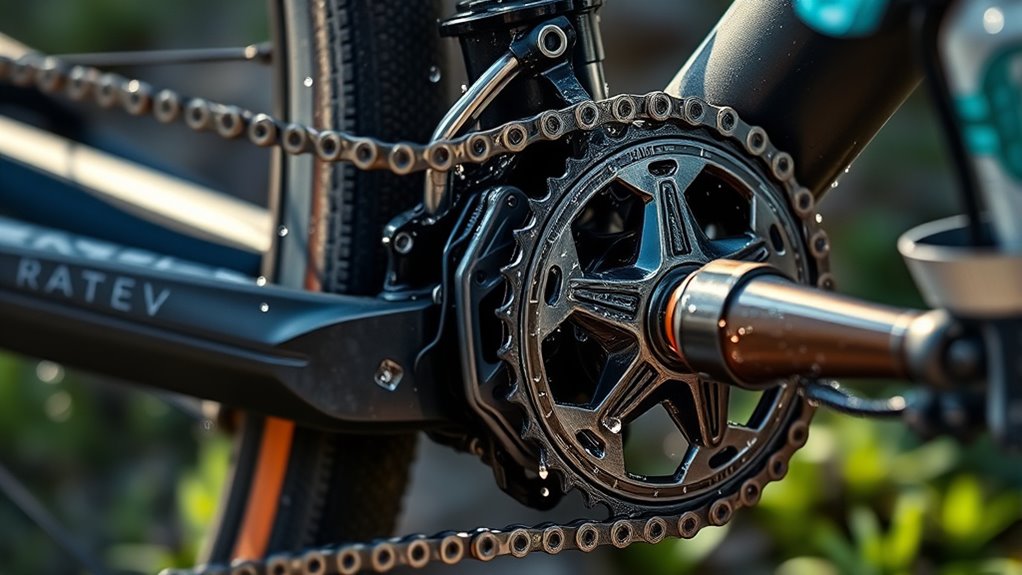

- Use brushes and degreaser to scrub drivetrain parts like chainrings, cassette, and derailleur for deep cleaning.

- Pay attention to the drivetrain, as a clean chain and gears improve performance.

- Finish by rinsing again to remove any remaining residue and preparing your gravel bike for drying.

Proper rinsing and cleaning keep your gravel bike running smoothly and extend its lifespan.

Lubricate and Inspect

Once your bike is clean and dry, it’s essential to lubricate and inspect the drivetrain to keep everything running smoothly. Start by thoroughly cleaning the chain with a degreaser and brushes to remove dirt and grime. After cleaning, inspect the chain for wear and check the derailleur, shifters, and brake cables for smooth operation. Apply a suitable lube—wet lube for muddy conditions or dry lube for dusty trails—to each chain link, ensuring it soaks in completely. Wipe off any excess to prevent dirt buildup. Finally, visually inspect the drivetrain components for signs of wear or damage. Proper lubrication and inspection help maintain ideal performance and extend the lifespan of your gravel bike’s drivetrain. Additionally, using the right lubrication technology can further improve your bike’s efficiency and longevity. Regularly monitoring component wear ensures early detection of issues before they lead to costly repairs, keeping your rides safe and enjoyable.

Proper Lubrication Techniques for Your Chain

To guarantee your gravel bike’s chain performs smoothly and lasts longer, applying lubricant correctly is essential. Start by cleaning the chain thoroughly to remove dirt and old lube. Then, apply a small amount of lubricant to each link while turning the cranks backward, ensuring even coverage. Use the right lubricant for your riding conditions: wax or dry lube for dusty, dry environments, or wet lube for muddy or wet conditions. Allow the lube to penetrate the chain links for several minutes, then wipe off any excess to prevent dirt buildup. Remember, over-lubricating attracts dirt and accelerates wear. Regularly reassess your chain’s condition and reapply lube every 100-200 miles or after cleaning. Proper technique keeps your drivetrain smooth and efficient.

Protecting Your Bike’s Frame and Components

Applying protective coatings to your bike’s frame and components shields them from dirt, moisture, and corrosion, helping maintain their appearance and functionality. Using products like CyclOn Bike Protector or CyclOn Matt Protector creates a dirt-resistant layer that makes cleaning easier and prevents grime buildup. Protecting unpainted parts such as rims, spokes, and chrome with CyclOn Vaseline or Vaseline Spray offers effective rust prevention. For exposed metal components, CyclOn Extreme Rust Prevention Spray adds an extra barrier against moisture and rust formation. Proper application of these coatings reduces the frequency of deep cleanings and minimizes wear caused by environmental exposure. By safeguarding your components, you extend your bike’s longevity and keep it performing at its best, no matter where your gravel rides take you.

Performing Major Maintenance and Repairs

When performing major maintenance, start by inspecting bearings for wear and lubricating them properly with products like Off Road Grease. Next, check your brake system, including pads, hoses, and fluid levels, and service or replace parts as needed to make certain of reliable stopping power. Finally, tighten all bolts to manufacturer specifications to keep your bike safe and performing at its best.

Bearing Inspection and Lubrication

Regularly inspecting and lubricating your bike’s bearings is essential for maintaining smooth performance and preventing costly repairs. Proper bearing maintenance involves checking for wear, corrosion, or dirt buildup, especially after muddy or wet rides. To guarantee peak function:

- Disassemble bearings like the headset, bottom bracket, and hubs for inspection.

- Clean bearings thoroughly with degreaser, then dry completely.

- Re-lubricate with CyclOn Off Road Grease, applying generously to contact surfaces.

- Seal bearings with CyclOn Sealing Paste or similar to guard against dirt and moisture.

This routine helps prevent premature failure, reduces friction, and extends component lifespan. Regular bearing inspection and lubrication keep your gravel bike running smoothly, no matter the terrain.

Brake System Servicing

Keeping your brake system in top shape requires more than just routine pad checks; it involves performing major maintenance and repairs when needed. You’ll need to disassemble brake calipers and rotors carefully, inspecting for wear or damage, and replacing components like brake pads before they’re less than 1mm thick. For hydraulic brakes, annual bleeding with the correct brake fluid (Mineral or DOT 5.1) and a proper bleed kit ensures maximum stopping power and prevents sponginess. Use CyclOn Assembly Paste for threaded connections and CyclOn Stay Fixed for carbon parts to guarantee secure fastening. If bolts are rusted or seized, spray with CyclOn 5×1 or Multi Oil Spray, and for stubborn parts, apply CyclOn Freezer Spray to ease disassembly.

| Step | Action | Tool/Material |

|---|---|---|

| 1 | Disassemble calipers and rotors | Basic tools, CyclOn sprays |

| 2 | Inspect for wear/damage | Visual check |

| 3 | Replace brake pads if thin | New brake pads |

| 4 | Bleed hydraulic brakes annually | Bleed kit, brake fluid |

| 5 | Reassemble and secure components | CyclOn Assembly Paste/Stay Fixed |

Bolt Tightening Procedures

Proper bolt tightening is essential to guarantee your gravel bike remains safe and performs at its best during major maintenance. Always refer to the manufacturer’s torque specifications to avoid over-tightening or under-tightening. Use a calibrated torque wrench to tighten bolts accurately, typically measured in Newton-meters (Nm). Regularly check bolts for signs of loosening, corrosion, or damage, especially after riding in muddy or wet conditions. For critical components like the stem, handlebars, or seat post, tighten bolts gradually in a crisscross pattern to ensure even force distribution. Avoid power tools unless they have adjustable torque settings, as excessive force can strip threads or damage parts. Proper torque application preserves component integrity and maintains your bike’s safety and performance.

Maintaining Protective Coatings and Preventing Rust

To protect your gravel bike from rust and corrosion, it’s essential to apply the right coatings and maintain them properly. Start by regularly applying CyclOn Extreme Rust Prevention Spray to exposed metal parts, especially after cleaning or riding in wet conditions, to enhance rust prevention. Protect unpainted components like spokes, rims, and chrome with CyclOn Vaseline or Vaseline Spray, which prevents moisture buildup that leads to corrosion. For painted frames and forks, use CyclOn Matt Protector or CyclOn Bike Protector to create a dirt-resistant barrier that reduces rust risk. Always dry your bike thoroughly after cleaning, paying close attention to joints and threaded areas prone to moisture retention. Periodically inspect vulnerable spots, and reapply protective coatings as needed to keep rust at bay.

Regular Inspection and Preventative Care Tips

Regular inspections are essential for catching potential issues early and keeping your gravel bike in top condition. By performing routine checks, you prevent small problems from turning into costly repairs. Focus on these key areas:

- Check chain wear regularly to ensure smooth shifting and prevent drivetrain damage.

- Conduct a thorough inspection of all bolts and components, tightening them to manufacturer torque specs.

- Examine brake pads for wear, replacing them before they become too thin.

- Spin wheels and cranks after cleaning to verify smooth rotation and identify wobbling or resistance.

Implementing preventative care through these inspections helps maintain peak performance, extends your bike’s lifespan, and minimizes unexpected breakdowns. Staying proactive with maintenance makes every ride safer and more enjoyable.

Frequently Asked Questions

How Do I Maintain My Gravel Bike?

To keep your gravel bike in top shape, you need to regularly inspect and tighten bolts to the correct torque. Clean it after muddy rides with gentle water and bike-specific cleaners. Lubricate the chain carefully, especially in wet conditions. Check your tire pressure and brakes before every ride for safety. Also, schedule annual maintenance like bearing servicing and brake bleeding to guarantee everything runs smoothly.

What Do I Need to Know About Gravel Bikes?

Ever wondered what makes gravel bikes unique? You should know they’re built for tough terrains with wider tires, durable materials, and relaxed geometry for comfort. They feature drop handlebars, disc brakes, and often tubeless tires for better traction and fewer flats. These bikes are versatile, ready for long rides on uneven surfaces. Recognizing these basics helps you appreciate their design and guarantees you get the most out of your gravel adventures.

How Often Should I Lube My Gravel Bike?

You should lube your gravel bike’s chain every 100-200 miles or once a week if you ride regularly in dry conditions. After riding in wet or muddy areas, reapply lubricant once everything’s dry to prevent rust and wear. In hot, dry climates, lube more often—about every 50-100 miles. Keep an eye on your chain for dryness or grit, and re-lube as needed to keep it running smoothly.

What Are the Downsides of a Gravel Bike?

The downsides of a gravel bike might surprise you. They often have wider tires and lower pressures, which can feel like pedaling through molasses on smooth pavement. Their lightweight frames aren’t built for heavy-duty racing or rugged terrain, and their geometry can make road riding less efficient. Plus, limited storage options and complex components can make long rides tricky and repairs more costly, so weigh these factors before hitting the trail.

Conclusion

Keep your gravel bike shining like a star on the trail by sticking to these simple maintenance tips. Regular cleaning, proper lubrication, and inspections are your best tools to extend your bike’s life and performance. Think of your bike as a trusted partner—taking care of it guarantees many adventures ahead. With a little effort, you’ll keep every ride smooth and trouble-free, turning your gravel bike into a true workhorse that’s ready for anything the road throws your way.