Mechanical drivetrains require you to manually shift gears using a lever and involve mechanical linkages, offering a tactile, hands-on experience. Electronic drivetrains automate gear changes with sensors and controls, providing smoother, more convenient shifts that reduce driver effort. While mechanical systems are simpler and easier to repair yourself, they need more maintenance over time. Electronic systems offer comfort but are more complex and costly to fix. Keep going to discover which option suits your driving style best.

Key Takeaways

- Mechanical drivetrains rely on manual gear shifting and mechanical linkages, requiring driver involvement.

- Electronic drivetrains automate gear changes with sensors and actuators, offering smoother transitions.

- Mechanical systems are simpler, easier to repair, and suitable for DIY maintenance; electronic systems are more complex.

- Mechanical systems demand regular adjustments and wear parts replacement, while electronic systems need software updates and diagnostics.

- Mechanical drivetrains provide a tactile driving experience, whereas electronic systems enhance comfort and driving ease through automation.

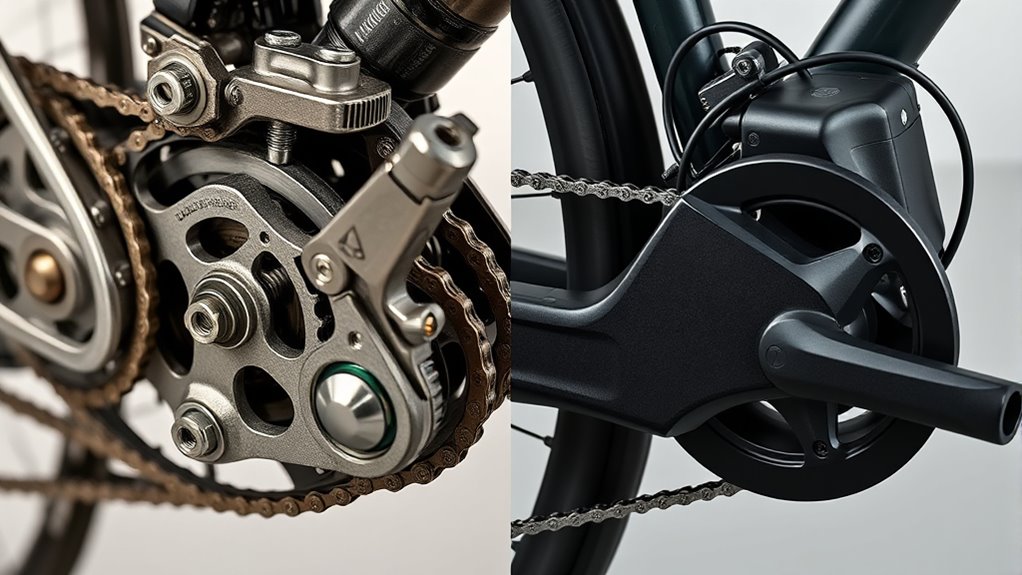

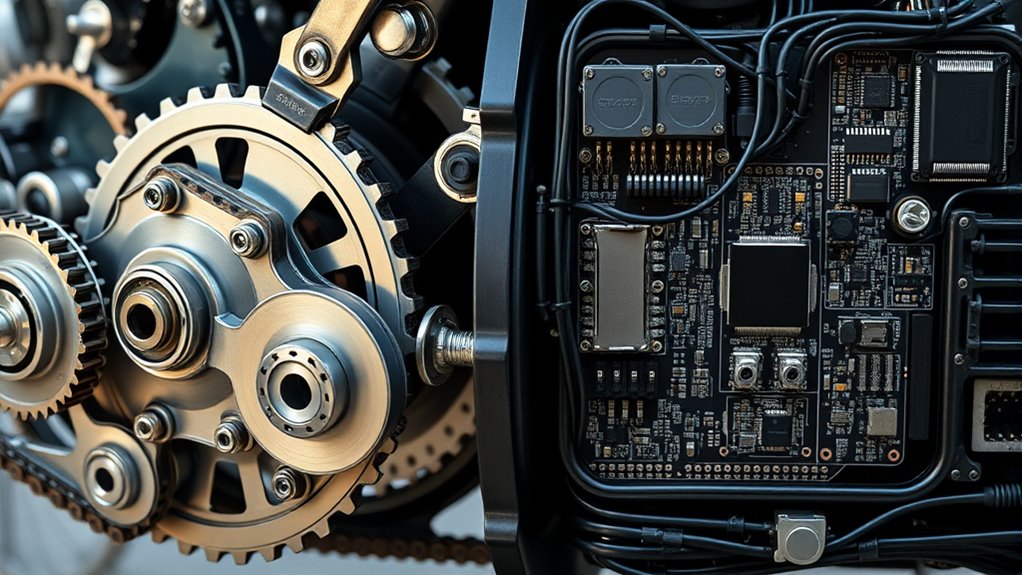

Have you ever wondered what sets mechanical and electronic drivetrains apart? The difference primarily lies in how each system handles gear shifting and their maintenance complexity. When you’re driving a vehicle with a mechanical drivetrain, gear shifting is a manual process. You physically move the gear lever, engaging and disengaging gears through mechanical linkages. This straightforward setup might seem simple, but it requires your active participation and a good feel for the clutch and shift points. Mechanical systems are generally less complicated internally, which means fewer electronic components to worry about. However, their maintenance can become more involved over time. You might need to regularly inspect and adjust linkages, replace worn clutch components, or lubricate moving parts. The mechanical nature makes these systems more accessible for DIY repairs, but it also means that wear and tear can lead to more frequent tune-ups.

On the other hand, an electronic drivetrain automates gear shifting through electronic controls and sensors. This setup eliminates the need for manual input, allowing your vehicle to shift gears seamlessly and swiftly, often improving overall driving comfort and efficiency. When you drive an electronic system, gear changes happen automatically based on data from sensors that monitor speed, throttle position, and engine load. Because of this, your involvement in gear shifting is minimal, which can be a significant advantage in stop-and-go traffic or long commutes. But this convenience comes with increased maintenance complexity. Electronic components, such as actuators, sensors, and control modules, are more delicate and susceptible to failures, especially in harsh environments. Repairing or replacing these parts may require specialized knowledge and tools, making maintenance more costly and time-consuming compared to mechanical systems. Additionally, software updates and diagnostics are often necessary to keep electronic drivetrains functioning at their best.

Both systems have their merits: mechanical drivetrains are reliable and simpler to understand, but they demand more hands-on maintenance and have a more tactile gear shifting process. Electronic drivetrains, conversely, offer smoother, more precise gear changes and less driver effort, but they introduce complexity that can translate into higher repair costs and reliance on electronic diagnostics. Your choice depends on your driving preferences and willingness to handle maintenance. If you prefer a more traditional approach and enjoy tinkering, a mechanical system might suit you better. Conversely, if you value comfort and technological convenience, the electronic drivetrain could be the way to go. Either way, understanding these distinctions helps you make an informed decision about which drivetrain aligns with your needs and expectations.

Frequently Asked Questions

How Do Maintenance Costs Compare Between Mechanical and Electronic Drivetrains?

You’ll find that maintenance costs for electronic drivetrains are generally lower than mechanical ones due to fewer moving parts and reduced repair frequency. Electronic systems tend to require less routine maintenance, like oil changes or belt replacements, which lowers ongoing expenses. However, when repairs are needed, electronic components can be more expensive to fix or replace, so consider the cost comparison carefully based on your usage and reliability needs.

Are Electronic Drivetrains More Eco-Friendly Than Mechanical Ones?

Electronic drivetrains are generally more eco-friendly than mechanical ones because they often use batteries with high efficiency, reducing energy waste. Plus, advances in manufacturing impact mean newer electronic systems are produced with less environmental harm. You’ll notice fewer emissions during operation, and as battery technology improves, their overall eco-friendliness increases. So, if you’re aiming for a greener ride, electronic drivetrains tend to be the better choice.

Which Drivetrain Type Offers Better Performance in Extreme Weather Conditions?

Think of electronic drivetrains as your trusty compass in extreme weather, offering superior climate resilience and quick adjustments. They tend to perform better under freezing or wet conditions because of fewer moving parts and sophisticated control systems. Mechanical drivetrains, while reliable, can struggle with reliability factors like corrosion or ice. So, if you need peak performance in harsh climates, electronic systems give you the edge, ensuring smoother, more dependable journeys.

How Does User Experience Differ Between Mechanical and Electronic Systems?

You’ll notice that mechanical systems often provide more ergonomic comfort and tactile feedback, making them feel more natural and intuitive to use. Electronic systems, however, offer smoother and quicker responses, but can sometimes lack the tactile cues you rely on. Your experience depends on your preference for tactile feedback versus seamless operation, but overall, mechanical setups give you more direct control, enhancing your confidence during precise maneuvers.

Can Mechanical Drivetrains Be Upgraded to Electronic Systems Later?

Sure, you can retrofit your mechanical drivetrain to an electronic system—if you’re willing to accept the challenge of costly, complex upgrade feasibility. While some components may be adaptable, most systems require significant modifications, making it less like a simple upgrade and more like a full rebuild. So, unless you’re enthusiastic to turn your bike into a tech Frankenstein, consider if the retrofit possibilities justify the effort.

Conclusion

Choosing between mechanical and electronic drivetrains is like picking a trusted old bicycle or a sleek new e-bike. I once watched a rider effortlessly switch gears on an electronic system, feeling like they had a magic wand. Studies show electronic systems offer smoother shifts and less maintenance, but mechanical drivetrains have that dependable, familiar feel. Ultimately, it’s about what feels right for you—whether you want tradition’s comfort or innovation’s thrill.